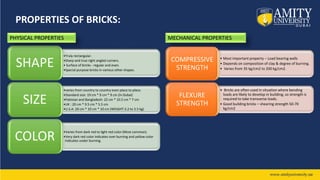

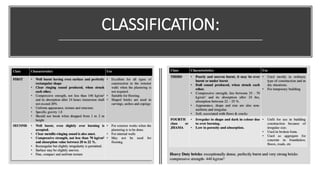

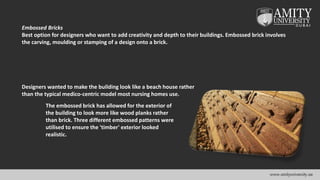

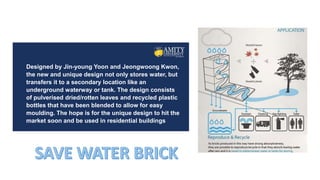

Sai Vamsi Krishna Putta conducted independent study research on bricks under the guidance of Ms. Vidya Mohanan. The document provides an introduction to bricks, discussing their basic properties such as shape, size, color and physical/mechanical properties. It also describes the various uses of bricks in construction, their composition, manufacturing process, classifications and recent advancements including innovative designs like cool bricks, embossed bricks, 3D printed bricks and a water-storing brick design.