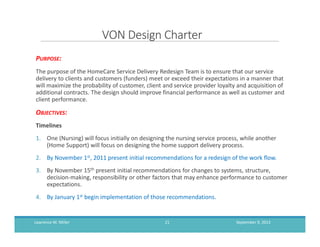

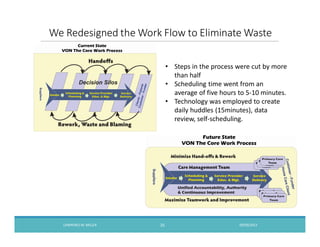

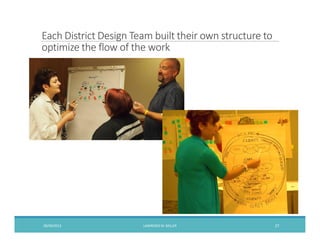

This document discusses the redesign of home care services at VON, a charitable organization providing home nursing care. It describes how VON formed design teams to analyze their work processes and redesign workflows to better meet customer needs. The redesign reduced process steps by over 50%, cut scheduling time from 5 hours to 5-10 minutes, and redesigned structures at the district level. The implementation included training all teams and defining new decision-making processes. The goal was to create a culture focused on continuous improvement to better serve customers.