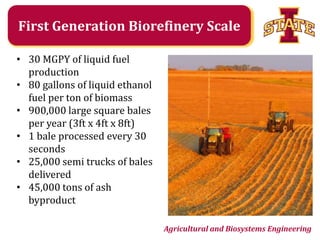

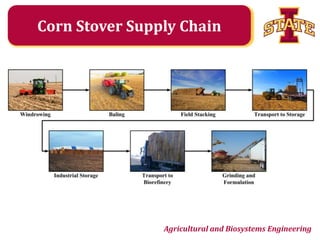

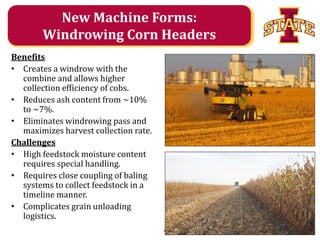

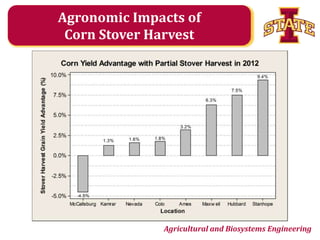

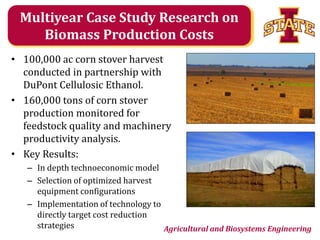

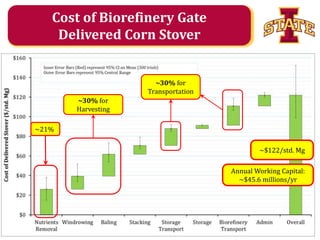

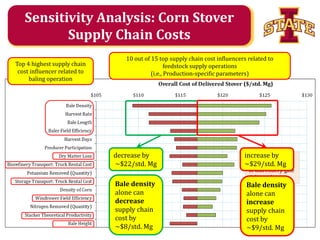

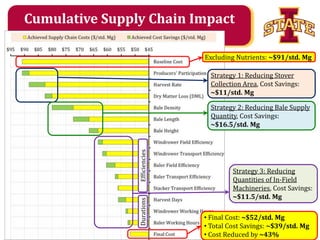

This document discusses machinery innovations needed to meet the increasing demand for biomass harvesting to support expanding biofuel markets. It summarizes Iowa State University's role in supporting the development of corn stover supply chains and biorefineries. The document outlines several innovations including increased harvest rates through baler improvements, higher density bales, single-pass harvesting machines, windrowing corn headers, and telematics to increase efficiency. It also reviews a case study on corn stover production costs and sensitivity analysis showing the largest cost factors are related to baling and feedstock supply operations. The goal is to reduce gate-delivered corn stover costs from $122 per tonne to $52 per tonne through strategies like reducing collection areas and