Steam Engine

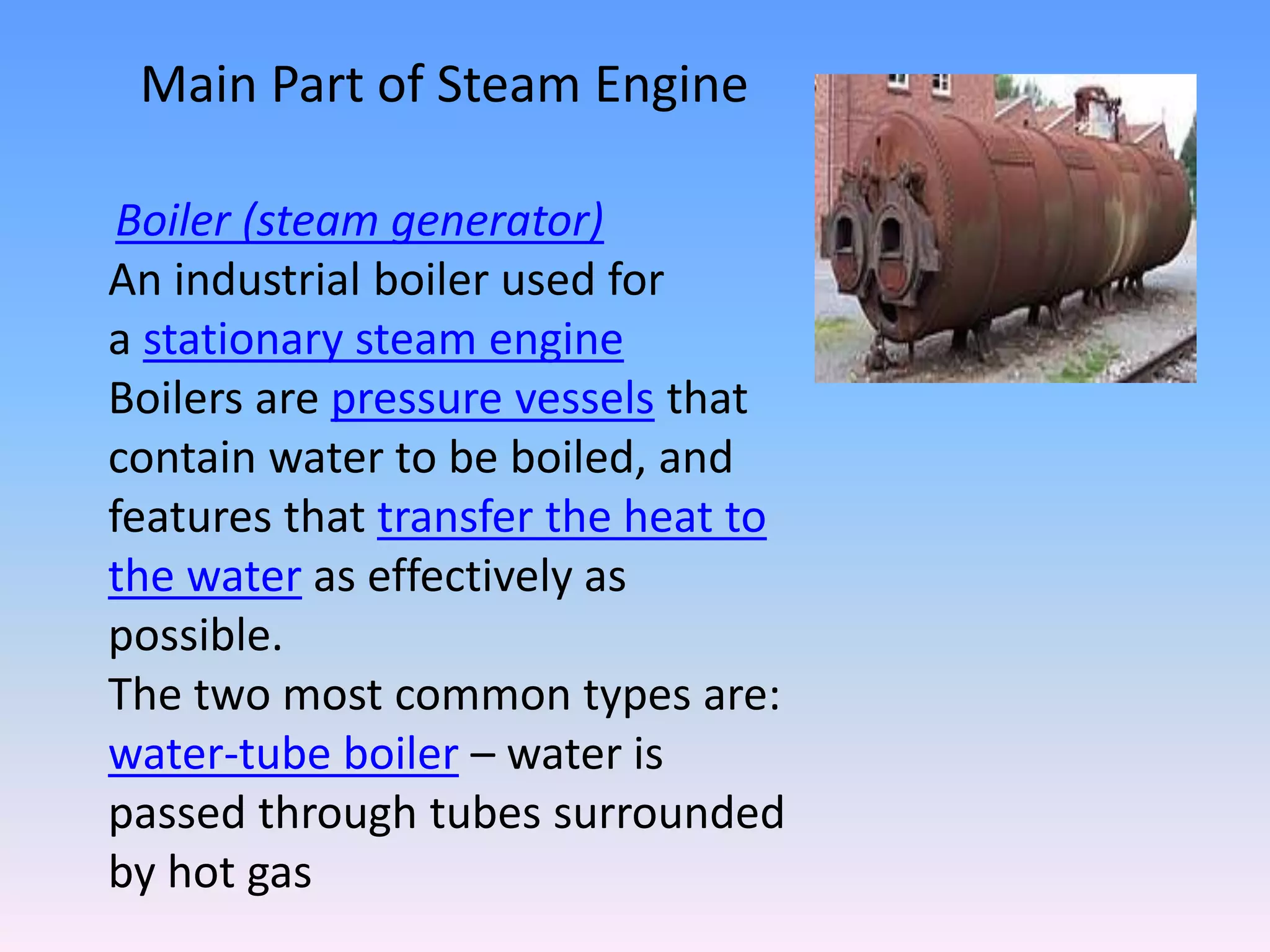

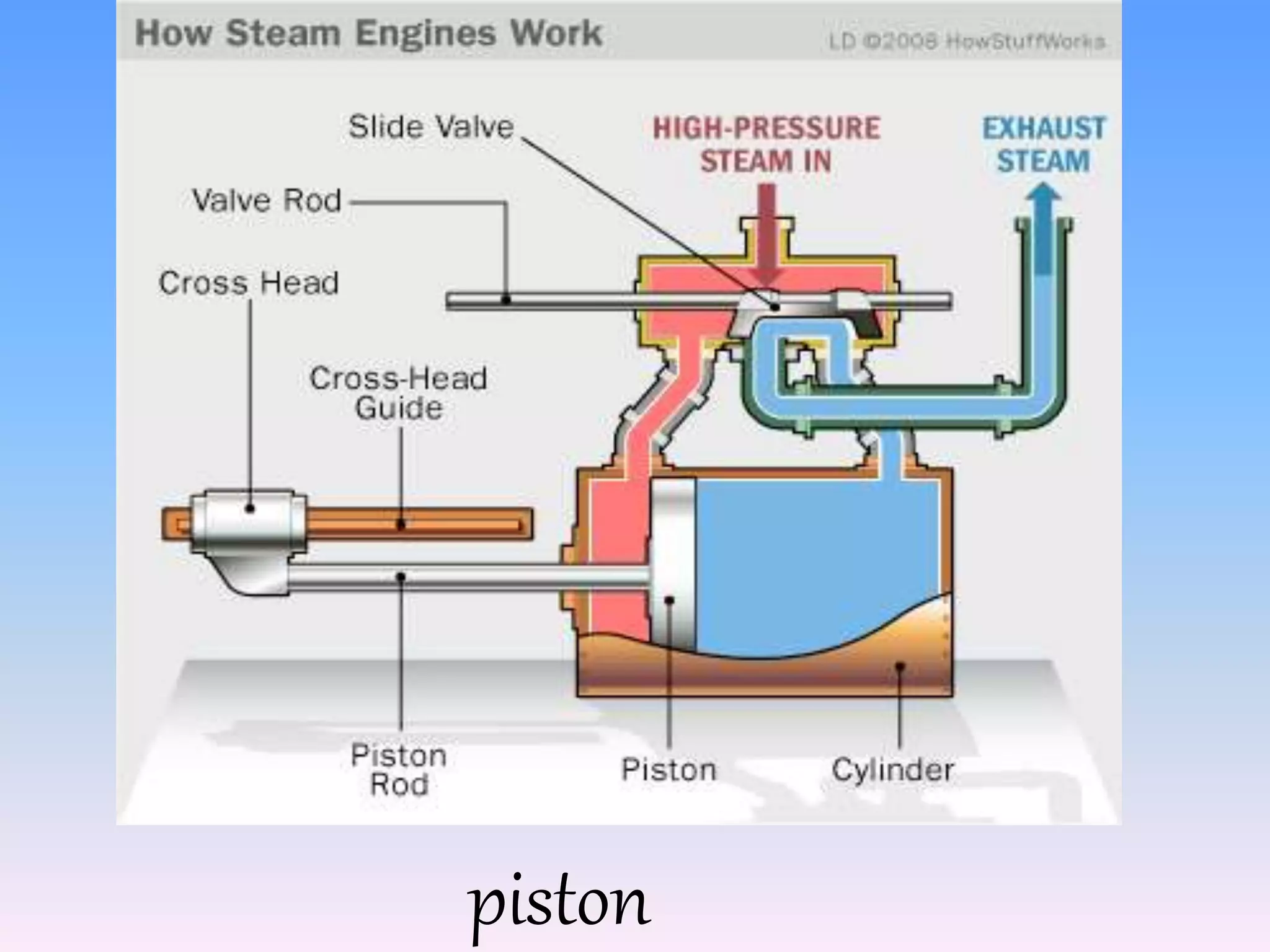

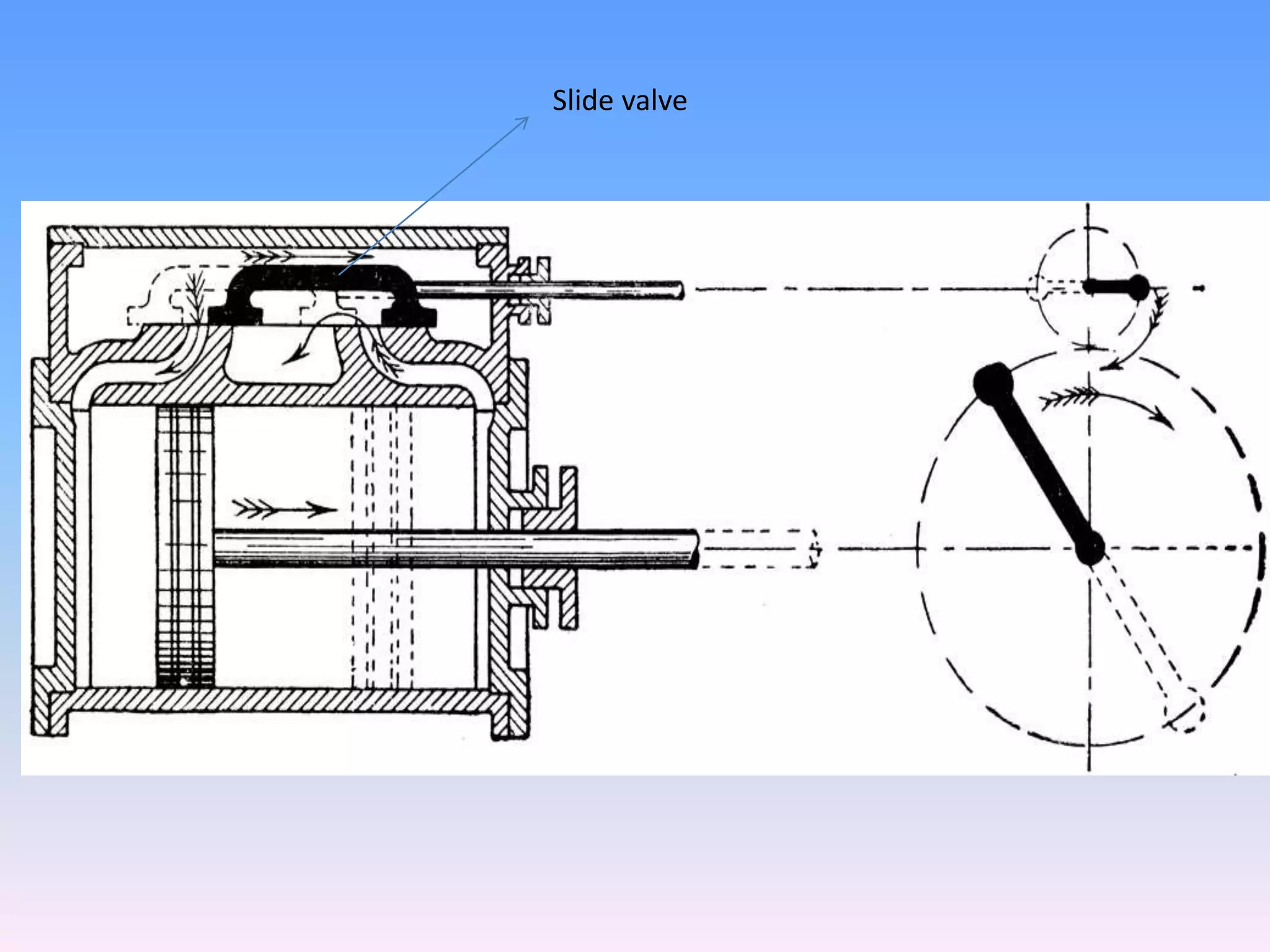

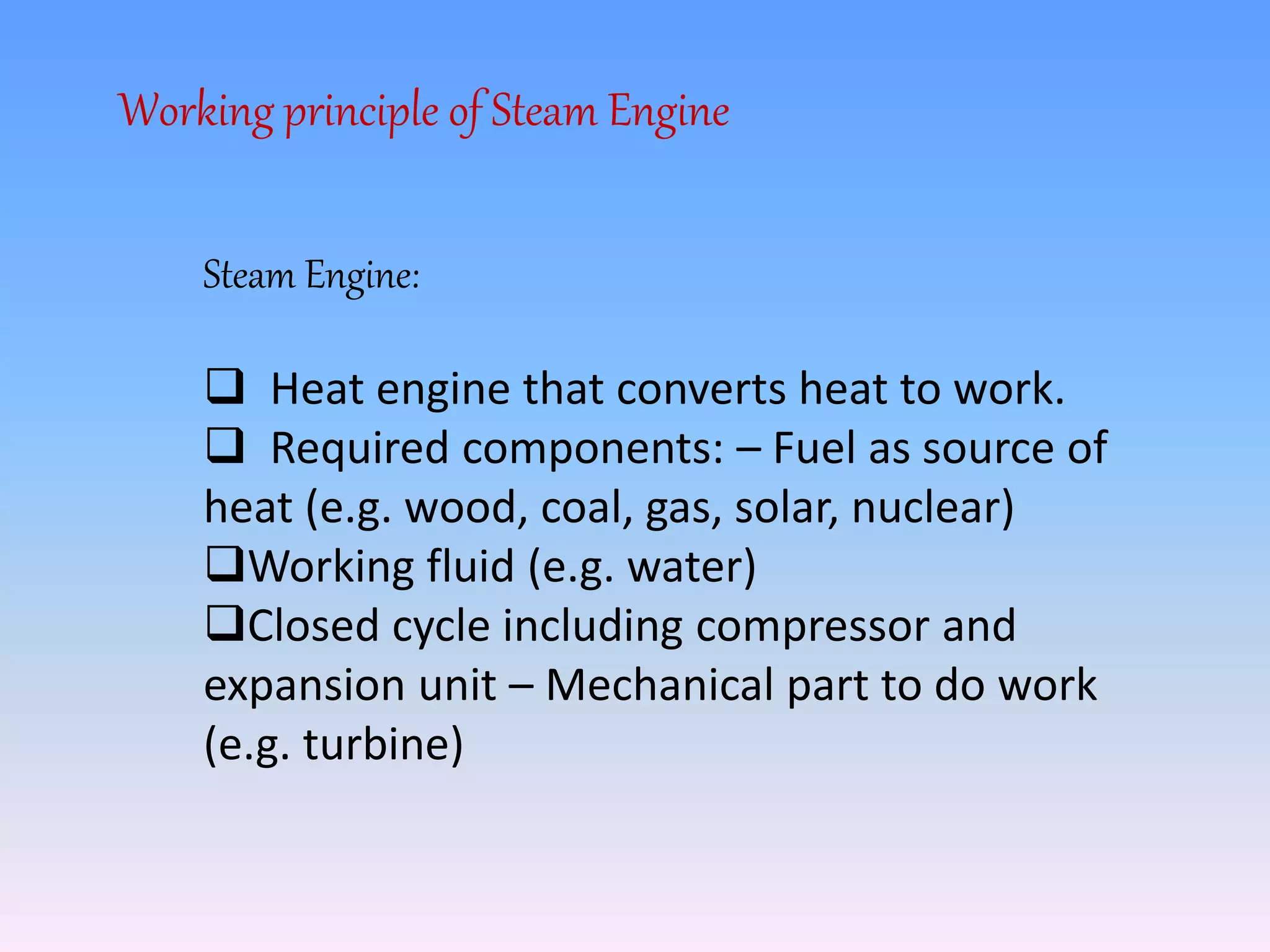

The document discusses the steam engine, including its history, working principle, main parts, types, advantages, and disadvantages. It notes that a steam engine converts heat from fuel like coal or wood into mechanical motion using steam as the working fluid. The key components are a boiler, piston, cylinder, and connecting rod. Historically, Thomas Newcomen invented the first practical steam engine in 1712 to pump water.

![Thermodynamic Cycle

• In the study of converting heat (thermo) into

mechanical (dynamic) action or work, many

cycles have been proposed to describe the

relationship between the heat you provide

and the work you get out.

• The goal is to maximize the efficiency of the

cycle, i.e. To increase the ratio [work

out/heat in].](https://image.slidesharecdn.com/mech-180916090324/75/steam-engine-working-and-principle-17-2048.jpg)