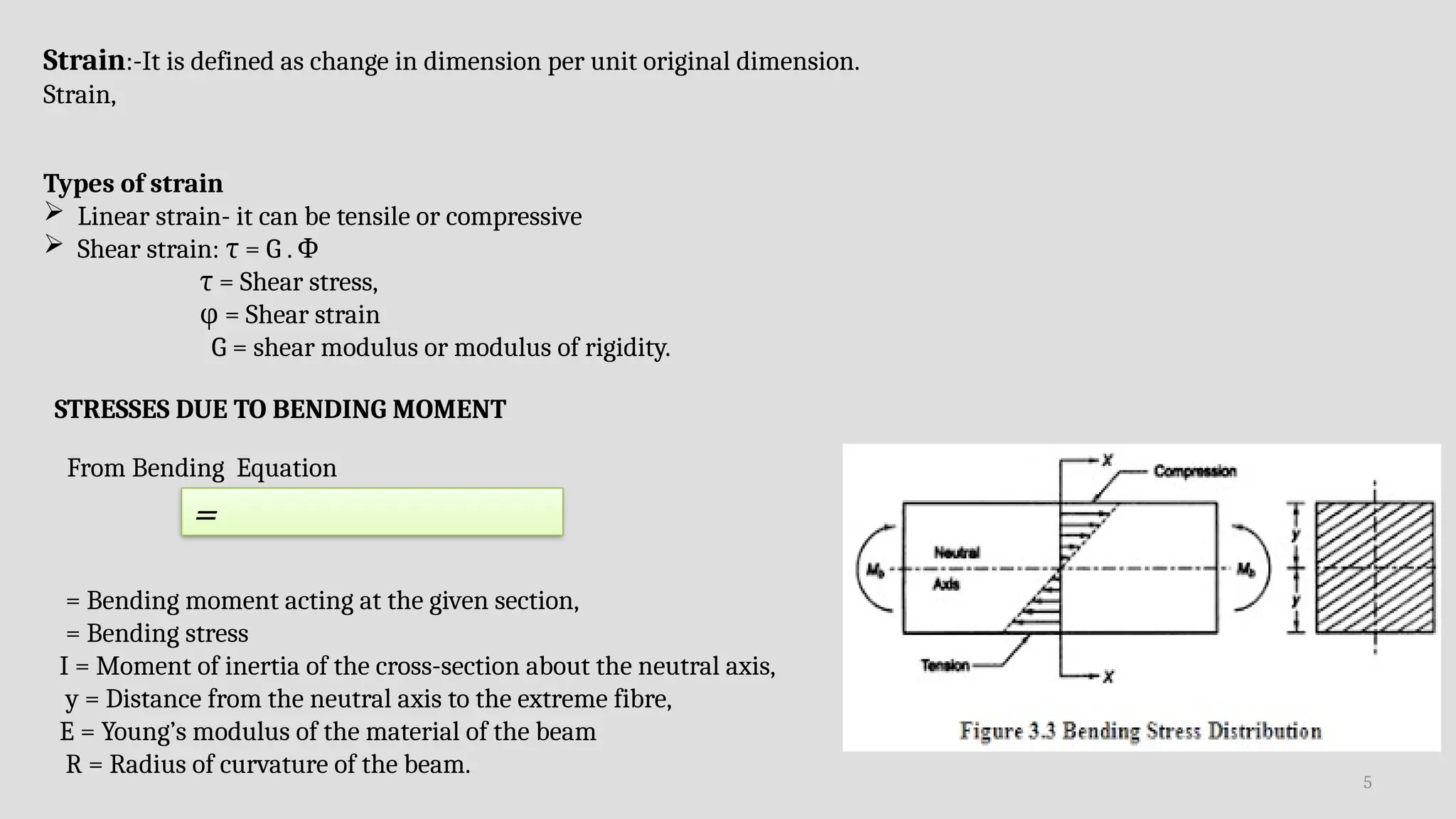

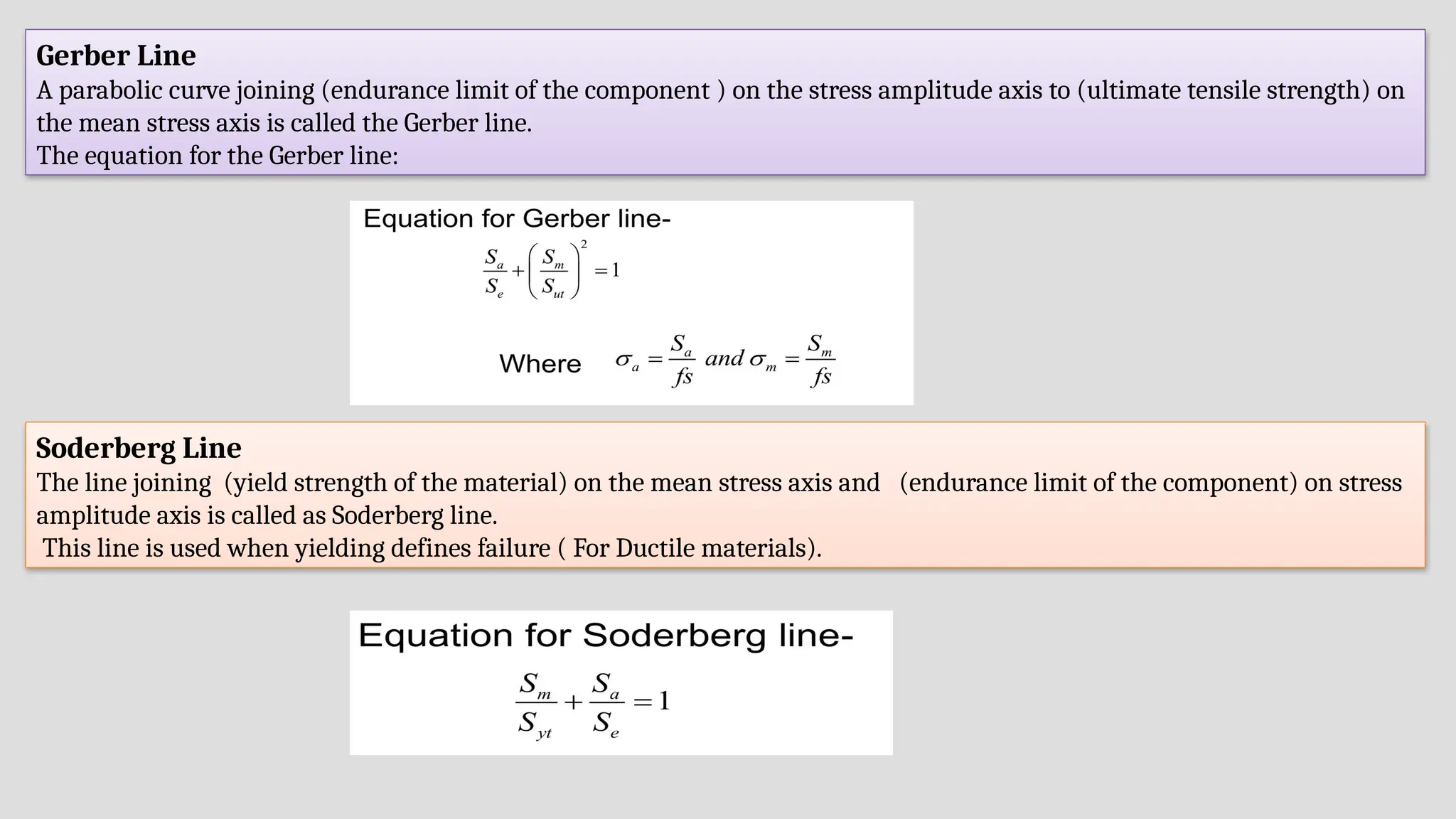

The document discusses various types of loads, stress, and strain in mechanical components, including static, dynamic, and impact loads, as well as their effects on material behavior. It covers concepts such as strain energy, factor of safety, fatigue loading, and stress concentration due to notches. Additionally, it details methods for evaluating material toughness, including Charpy and Izod impact tests, as well as the relationship between endurance limits and material properties.