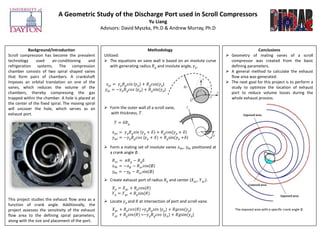

The document describes the methodology used to model the geometry of scroll vanes in a scroll compressor. It involves using involute curves defined by parameters like generating radius and involute angle to determine the equations for the outer wall and thickness of each vane. Mating vanes are then positioned using a crank angle. An exhaust port is created using a radius and center point and its intersection with the vane walls is calculated. The goal is to study exhaust flow area over the crank angle and how parameters like vane geometry and port size and placement affect it. The project aims to optimize port location to reduce volume losses during exhaust.