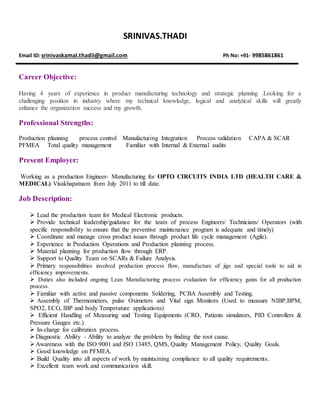

Srinivas Thadi is a production engineer with over 4 years of experience in manufacturing medical devices. He currently works at Opto Circuits India Ltd in Visakhapatnam, where he leads production teams and coordinates various functions like production planning, quality assurance, and process improvement. Some of the key products he has experience with include thermometers, pulse oximeters, and vital sign monitors. He is proficient in manufacturing processes, quality management systems, and calibration of electronic equipment. Previously he interned at Vizag Steel Plant where he maintained electrical and electronic equipment. Srinivas holds a B.Tech in Electronics and Communication Engineering as well as a post-graduate diploma in Industrial Engineering and Management.