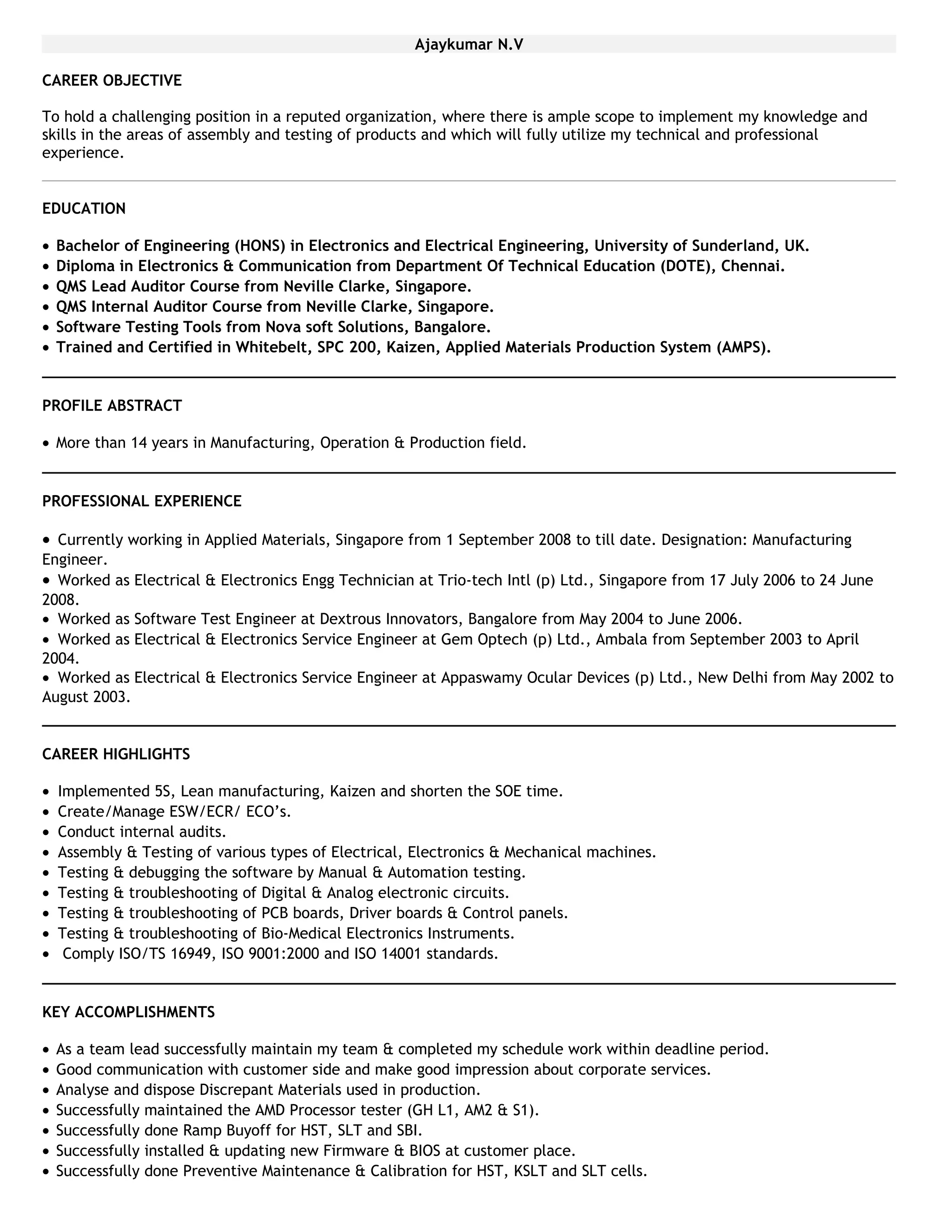

Ajaykumar N.V has over 14 years of experience in manufacturing, operations, and production. He holds a Bachelor's degree in Electronics and Electrical Engineering from the University of Sunderland in the UK. Currently, he works as a Manufacturing Engineer for Applied Materials in Singapore, where his responsibilities include testing new hardware and software, implementing quality processes, and troubleshooting production line issues. Prior to this, he worked in various engineering and testing roles for companies in Singapore and India, gaining experience in electronics, software testing, and maintaining quality standards.