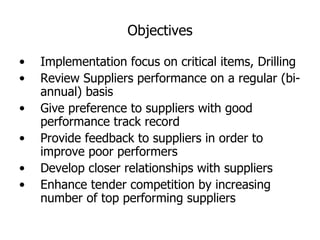

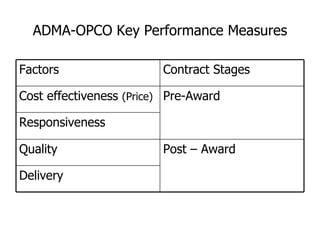

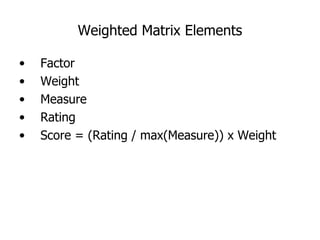

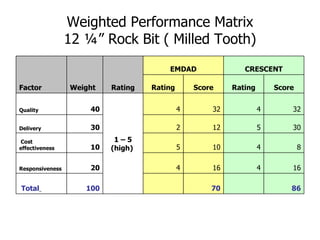

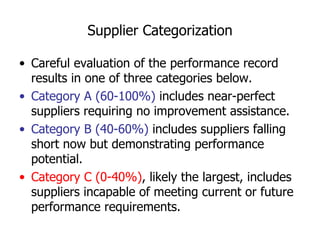

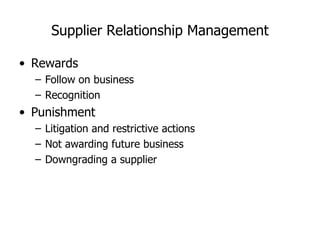

The document summarizes supplier performance measurement and optimization at ADMA-OPCO. Key performance measures include delivery, quality, responsiveness, and cost effectiveness. Suppliers are evaluated and categorized as A, B, or C based on their performance scores. Rewards and punishments are used to incentivize supplier performance and improve relationships. The current evaluation procedure is being updated to include bid price analysis and improve collaboration between procurement and vendor teams.