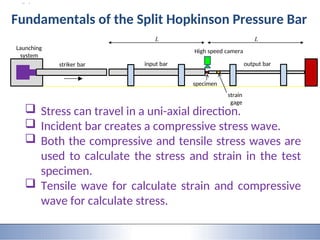

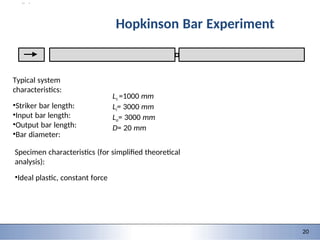

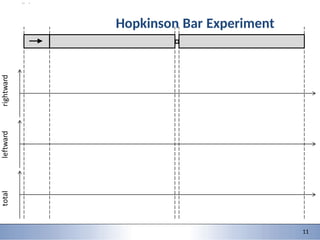

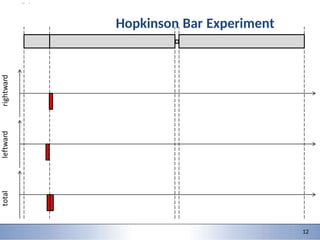

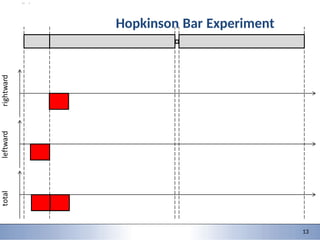

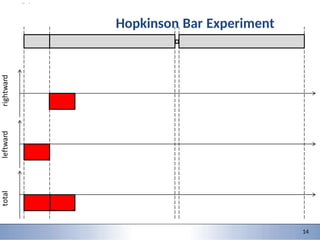

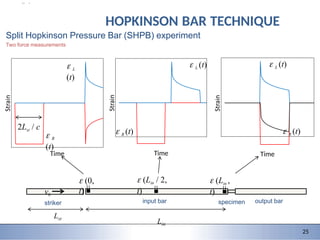

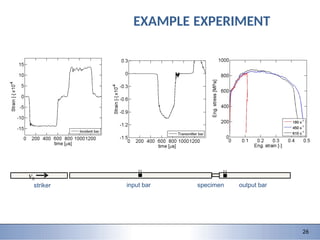

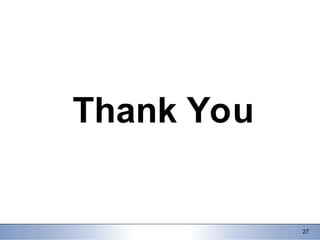

The document discusses the dynamic behavior of materials and structures, focusing on research regarding the high strain rate behavior of various materials, including tool steels and aluminum alloys. It highlights the need for more research on additive manufactured specimens, particularly in the context of tool steel materials in automotive applications. The proposed project aims to set up a split Hopkinson pressure bar for testing, characterize both additive and traditional materials, and validate findings through actual die industry applications.

![9/28/2015 1 1

151-0735: Dynamic behavior of materials and structures

2

Review on Impact of Dies

Biswas and Ding [26] have studied numerical simulations to gain insights

on the observed material behaviour and a general understanding of the

dynamic responses of AM porous metals.

Sahu et al. [28] investigated the high strain rate behaviour of two

twinning induced plasticity steels, wherein the stability of austenite was

found to be high at higher strain rates than at lower strain rates.

Singh et al. [29-30] studied the dynamic compressive as well as tensile

properties of a structural steel using SPHB and determined the material

properties for the existing JC model.

Bobbili et al. [31] conducted compression SHPB tests on high strength

armor steel tempered at various temperatures in the range of 500-6500

C.

Pothnis et al. [32]studied the effect of strain rate on tensile properties of

IS 2062 mild steel and 7075 aluminium alloy using tensile SHPB apparatus](https://image.slidesharecdn.com/splithopkinsonpressurebar-241118132017-fd34c73c/85/Split-Hopkinson-Pressure-Bar-in-Sheet-Metal-2-320.jpg)