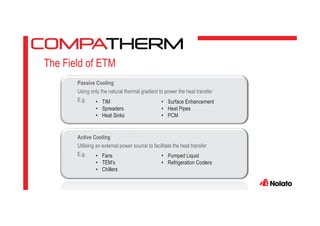

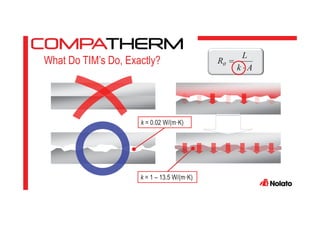

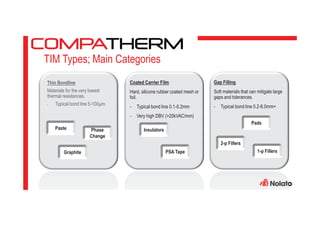

The document provides an in-depth exploration of heat transfer physics, detailing mechanisms such as conduction, convection, and radiation, along with Fourier's law and Newton's rule. It also covers thermal management strategies, including passive and active cooling methods, and the characteristics of various thermal interface materials (TIMs) used for efficient heat dissipation. Additionally, it emphasizes the importance of material selection for thermal management applications and outlines the unique capabilities of Compatherm in the thermal materials industry.

![Conduction

Thermal Conductivity (k)

► Unit W/(m·K)

► Value determined by

material

Magnitude Material k [W/(m∙K)]

10-2 Still air ~0,02

10-1 Polymers ~0,2

100 TIM’s (typical) ~1+

101 Stainless steel ~20

102 Aluminium extrusion ~200

103 Graphene ~2 000

104 Heat pipes (equiv.) <20 000](https://image.slidesharecdn.com/nolatothermalsolutions-180417190431/85/Nolato-thermal-solutions-pdf-5-320.jpg)

![4

[W/(m·K)] [Shore00] [g/cm3

] [VAC/mm] [mm]

9410 1 40 2.37 5 000 0.25 - 5.00 Pink

9411 1.3 9 2.50 5 000 0.25 - 5.00 Lt Blue

9420 2 40 2.73 5 000 0.25 - 5.00 Lt Blue

9421 2.5 40 2.70 5 000 0.50 - 5.00 Lt Brown

9422 2 25 2.70 5 000 0.50 - 5.00 Lt Blue

9430 3 60 2.65 400 0.25 - 5.00 Grey

9431 3 40 3.10 > 8 000 0.25 - 5.00 Blue

9432 3 10 2.92 > 7 000 1.00 - 5.00 Brown

9433 3 28 2.65 400 0.25 - 5.00 Grey

9440 4 40 3.10 > 8 000 0.75 - 5.00 Green

9441 4 8 3.10 > 8 000 1.00 - 5.00 Green

9450 5 40 3.10 > 7 000 0.50 - 5.00 Grey

9451 5 28 3.07 > 5 000 0.30 - 5.00 Grey

9452 5 60 3.10 > 5 000 1.00 - 5.00 Grey

9470 7 40 2.55 1 500 1.00 - 5.00 Lt Grey

9471 7 40 3.10 8 000 1.00 - 5.00 Pink

9472 7 20 2.55 1 500 1.00 - 5.00 Lt Grey

9473 7 20 3.10 8 000 1.00 - 5.00 Pink

9480 8 40 3.10 8 000 0.50 - 5.00 Blue

Material Code

Thermal

Conductivity

Hardness Density Colour

Dielectric

Breakdown Voltage

Thickness Range](https://image.slidesharecdn.com/nolatothermalsolutions-180417190431/85/Nolato-thermal-solutions-pdf-27-320.jpg)

![5

[W/(m·K)] [Shore00] [g/cm3

] [VAC/mm] [mm]

9610 13.5 55 2.70 n/a 1.00 - 5.00 Dk Grey

Material Code

Thermal

Conductivity

Hardness Density Colour

Dielectric

Breakdown Voltage

Thickness Range](https://image.slidesharecdn.com/nolatothermalsolutions-180417190431/85/Nolato-thermal-solutions-pdf-28-320.jpg)

![7

[W/(m·K)] [Pa·s] [g/cm3

] [VAC/mm] [h] [h]

9310 1.8 110 2.8 5 000 3 18 Blue + White

9343 4 350 3.1 5 000 4 24 Pink + White

9344 4 300 3.1 5 000 2.5 12 Green + White

Pot Life

Cure Time

@25°C

ColourMaterial Code

Thermal

Conductivity

Viscosity

(mixed)

Density

Dielectric

Breakdown Voltage

Material Code Thermal Conductivity Flow Rate Density

Dielectric

Breakdown Voltage

Colour

[W/(m·K)] [g/min] [g/cm3] [VAC/mm]

9240 4.5 22 3.2 >5 000 White](https://image.slidesharecdn.com/nolatothermalsolutions-180417190431/85/Nolato-thermal-solutions-pdf-30-320.jpg)

![9

[W/(m·K)] [cP] [g/cm3

] [µm] [K·cm2

/W]

9520 2.5 80 000 2.2 20 0.08 Grey

9521 2 110 000 2.8 20 0.20 White

9522 2.8 225 000 2.8 20 0.08 Grey

9530 3 80 000 2.2 20 0.07 Grey

9540 4.3 300 000 2.3 20 0.06 Grey

9541 4.3 500 000 2.3 20 0.06 Grey

Minimum Achievable

Bondline Thickness

ColourMaterial Code

Thermal

Conductivity

Viscosity Density

Thermal Resistance

@40PSI](https://image.slidesharecdn.com/nolatothermalsolutions-180417190431/85/Nolato-thermal-solutions-pdf-32-320.jpg)