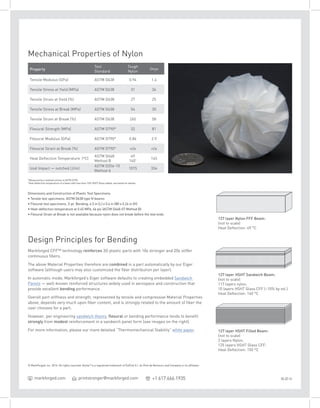

This document provides specifications and mechanical properties for various fiber composite test specimens used in tensile, compressive, and flexural testing, including differences between carbon fiber, Kevlar, and fiberglass composites. It details dimensions of test samples, the capabilities of the Mark Two 3D printer, and the testing standards utilized, emphasizing that part performance can vary based on design and testing conditions. Additionally, disclaimers regarding warranties and the suitability of data for application are clearly stated.