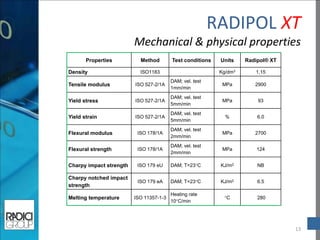

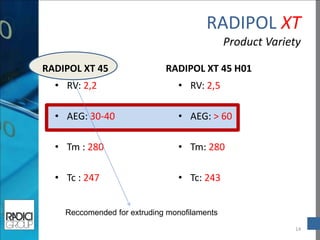

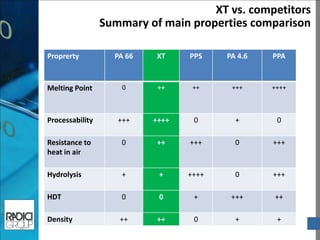

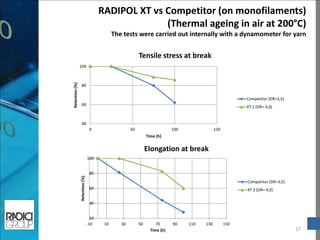

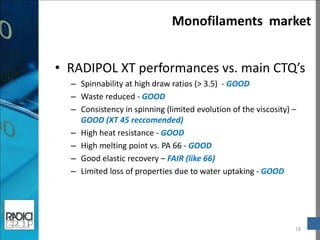

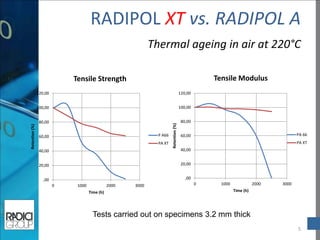

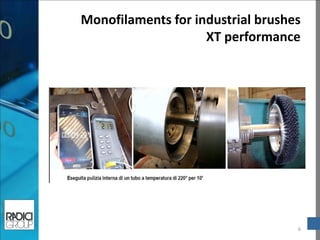

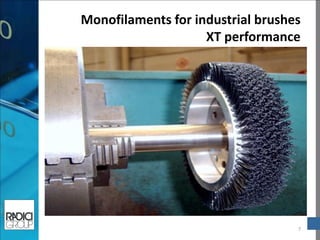

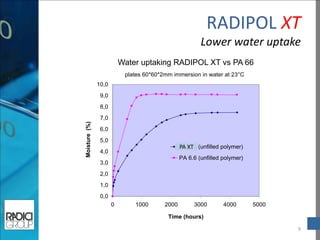

Radipol XT is a high temperature polymer suitable for applications such as monofilaments for industrial brushes and filters. It offers higher resistance to thermal oxidation up to 230°C compared to competitors and absorbs less water and moisture than PA 66. Radipol XT maintains over 80% of its tensile strength and modulus even after 3000 hours at 220°C. It also absorbs around 25% less moisture than PA 66 when exposed to humid conditions. Radipol XT is well-suited for monofilament applications due to its high heat resistance, low moisture absorption, and ability to be spun into filaments with draw ratios over 3.5.

![11

RADIPOL XT Lower moisture uptake

About 25% less moisture uptake for RADIPOL XT

000

001

001

002

002

003

003

004

004

005

005

0

12

24

36

48

60

72

84

96

108

120

132

144

156

168

180

Moisture uptake [%]

Time [h]

Moisture uptake

60°C - 70% HR on plaques 2.0mm thick

PA66

XT](https://image.slidesharecdn.com/radipolxtformonofilament-141007070411-conversion-gate01/85/Radipol-XT-for-monofilament-11-320.jpg)