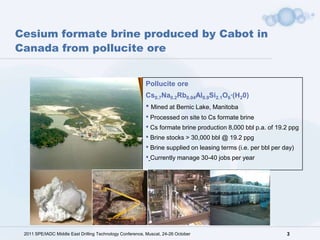

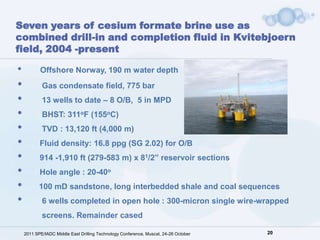

This document discusses the use of cesium formate brine as a drilling, completion, and workover fluid for high pressure, high temperature (HPHT) gas wells over the past 10 years. Some key points:

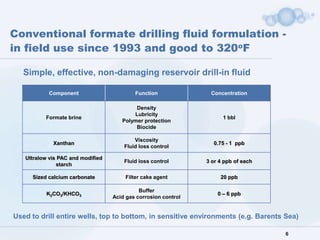

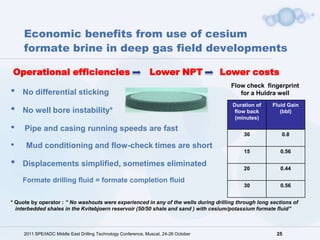

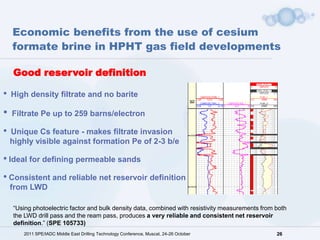

- Cesium formate brine is non-toxic, compatible with reservoirs, and less corrosive than other brines like bromide brines.

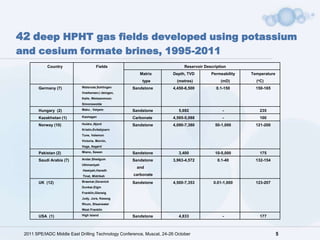

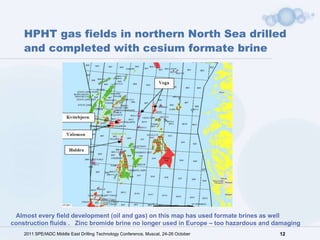

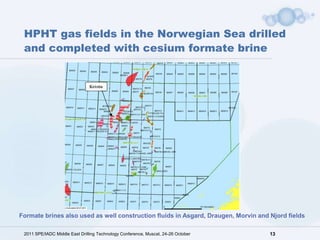

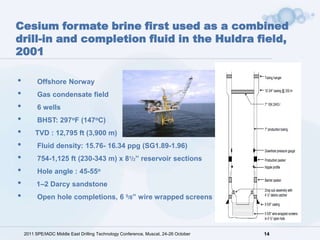

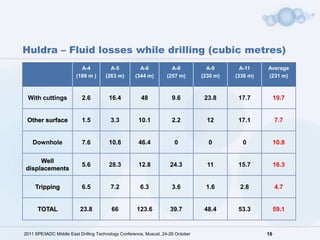

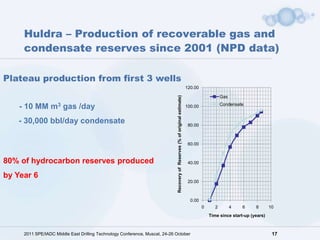

- It has been used successfully in over 40 HPHT gas fields worldwide, enabling improved well control and safer drilling operations compared to other fluids.

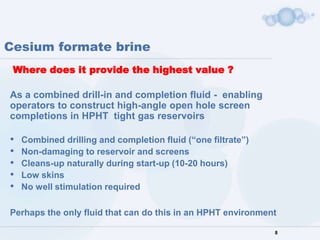

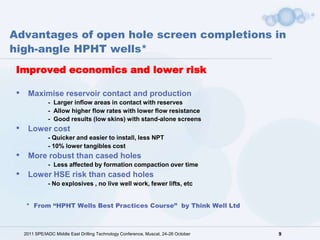

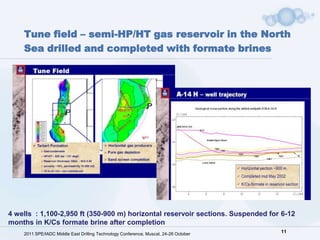

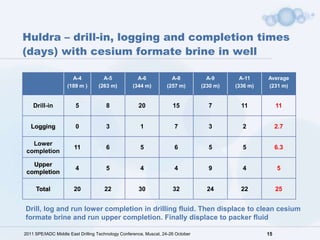

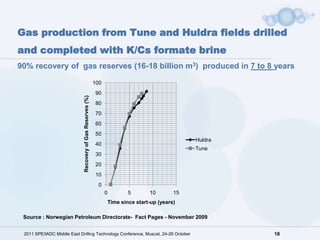

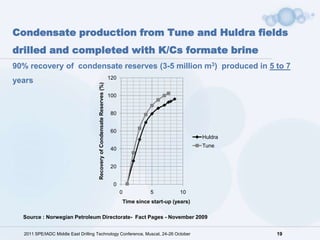

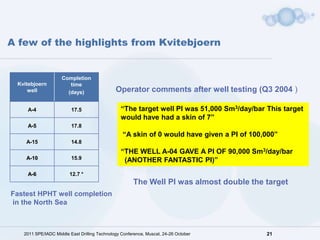

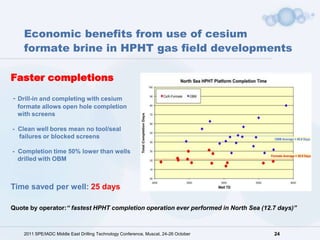

- Specific examples from the North Sea highlight its effectiveness as a combined drill-in and completion fluid, resulting in low skin factors and high well productivity.