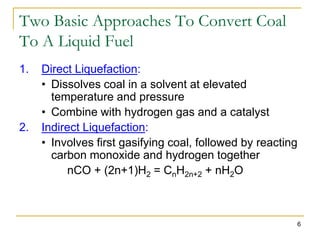

Coal liquefaction and carbonization are processes to convert coal into liquid and gaseous fuels. Liquefaction increases the hydrogen to carbon ratio in coal to produce synthetic crude oil or other liquid hydrocarbon fuels through either direct or indirect methods. Carbonization is the process of heating coal to drive off volatile liquid and gaseous products, leaving behind a solid residue called coke. High-temperature carbonization produces metallurgical coke for blast furnaces, while low-temperature carbonization was developed to produce town gas and smokeless fuel.