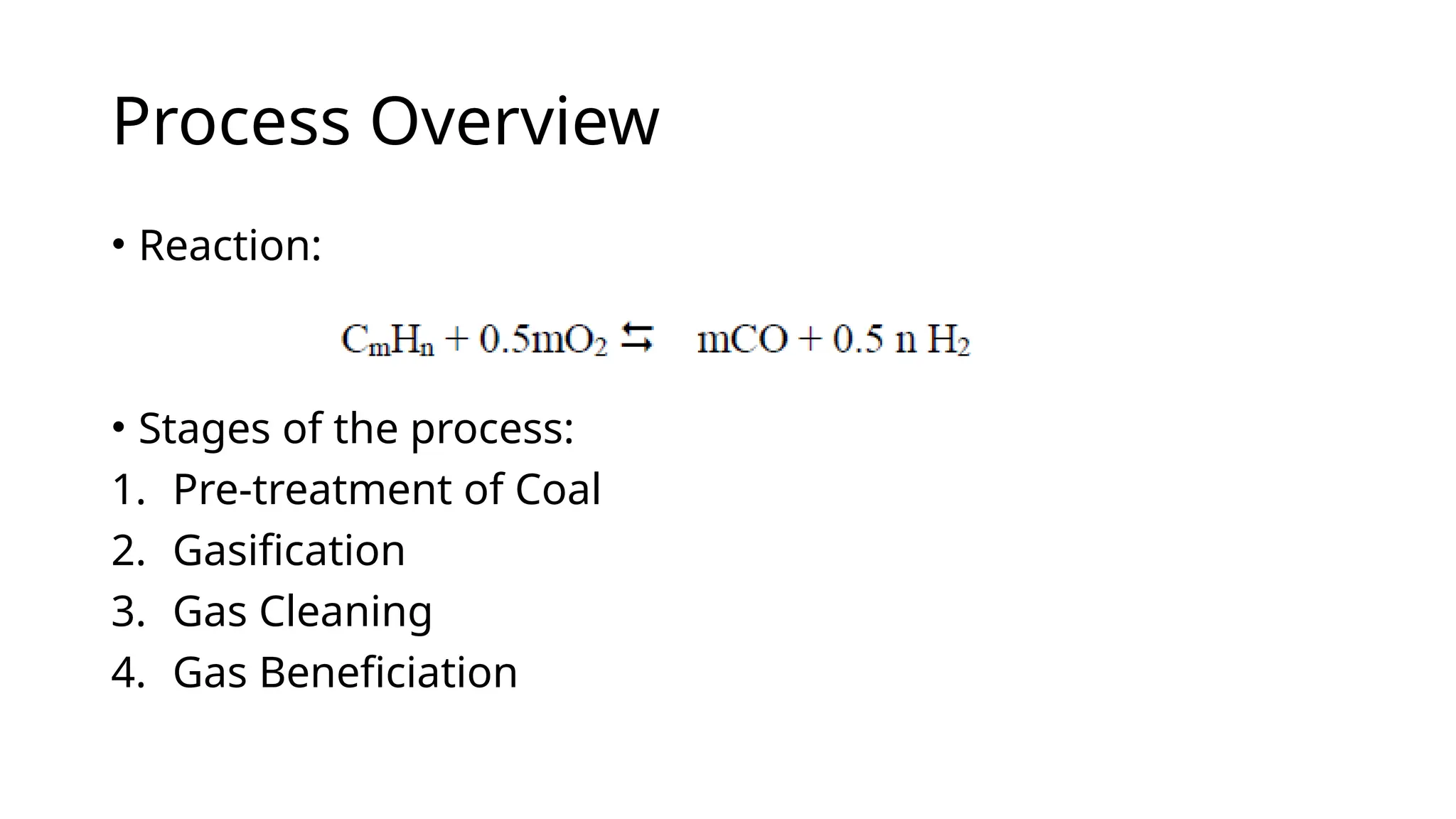

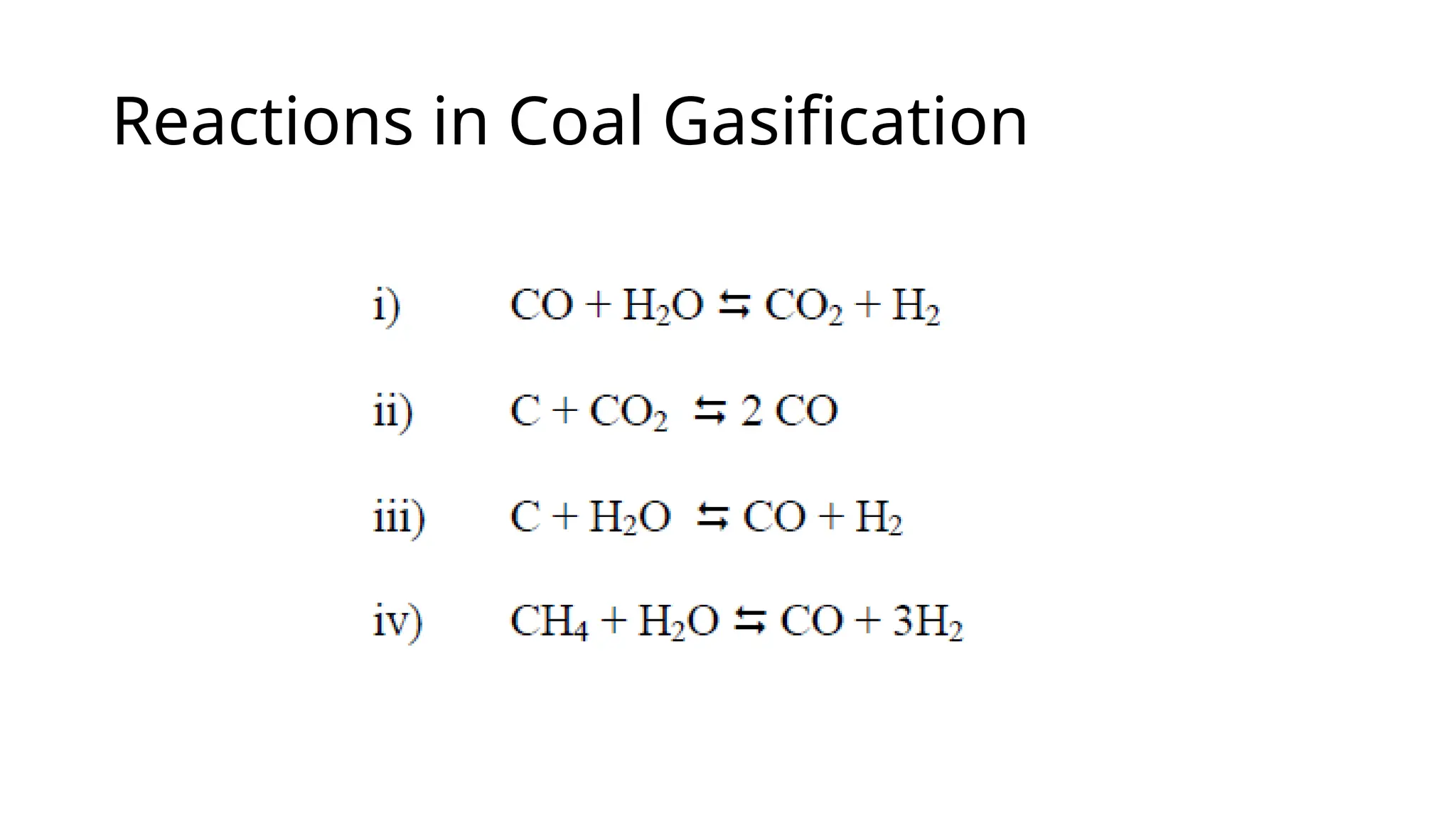

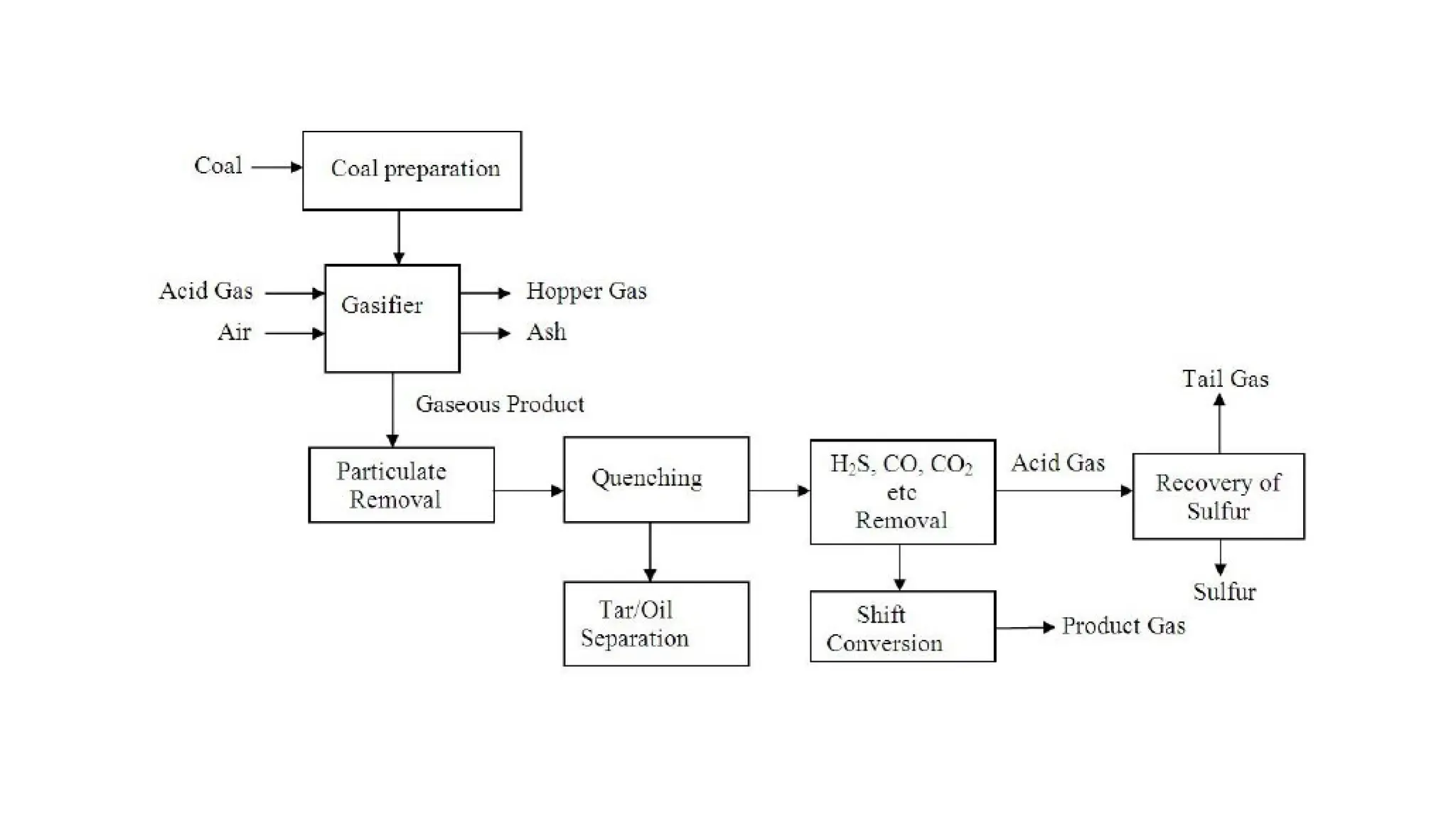

Coal gasification technology efficiently converts coal into power, chemicals, fertilizers, and fuels by decomposing it into synthesis gas (syngas) using steam and oxygen at high temperatures and pressures. Key applications include power generation, fertilizer production, methanol synthesis, and hydrogen production, with specific focus on the selection of suitable coal and essential gas cleaning processes. Different gasification techniques, such as fixed bed, moving bed, fluid bed, and entrained-flow gasifiers, vary in operational efficiency and suitability for different coal types.