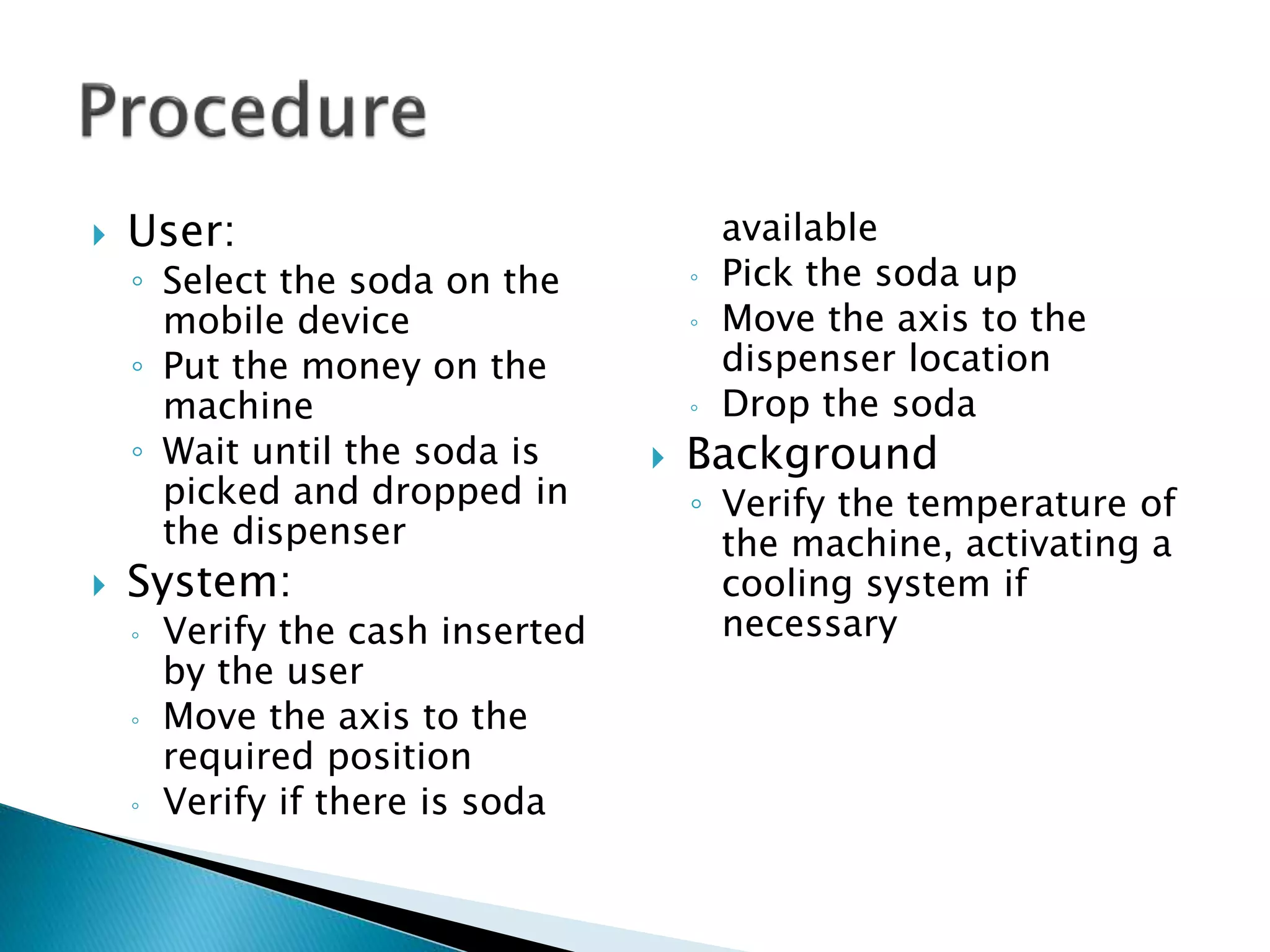

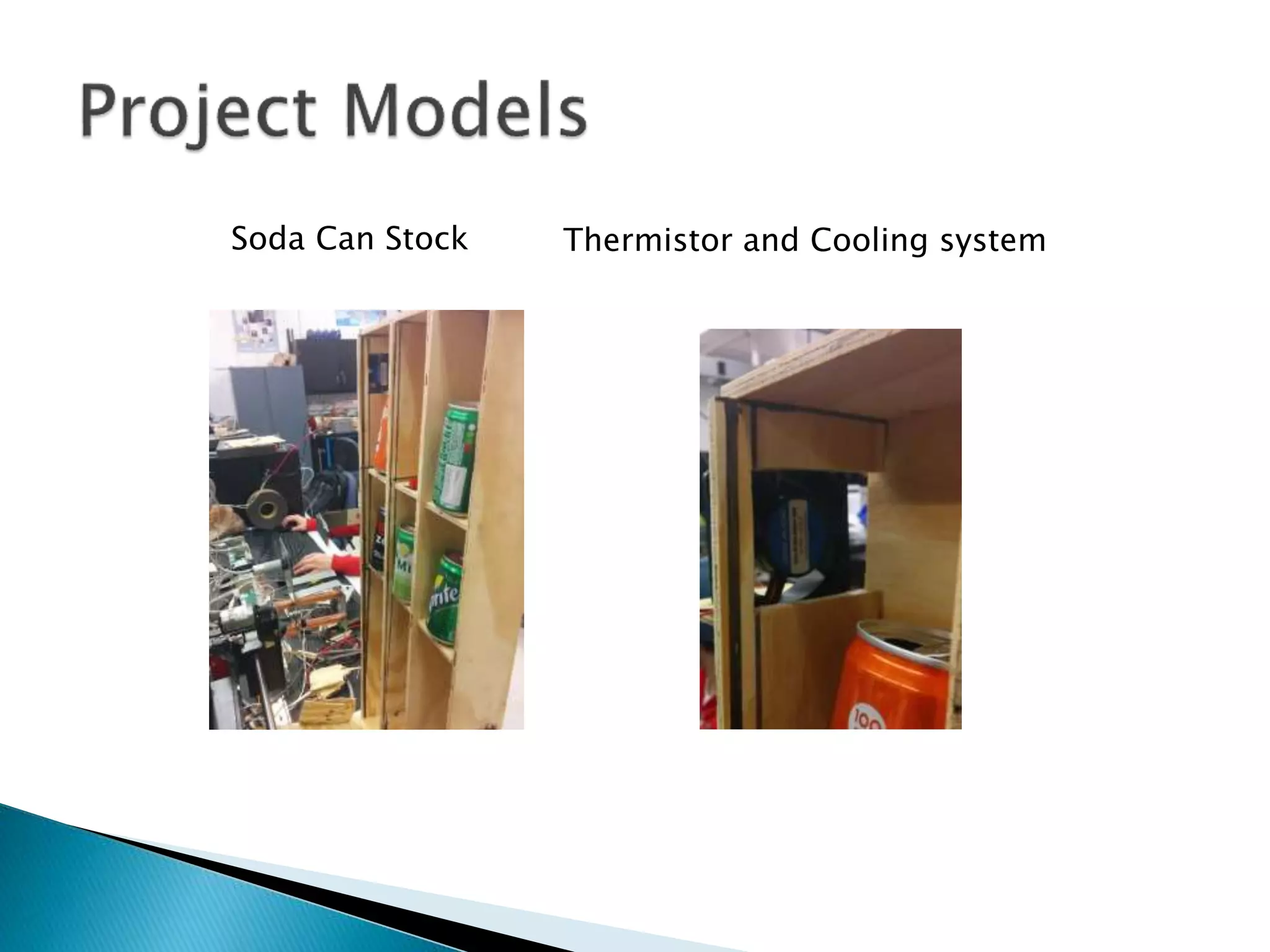

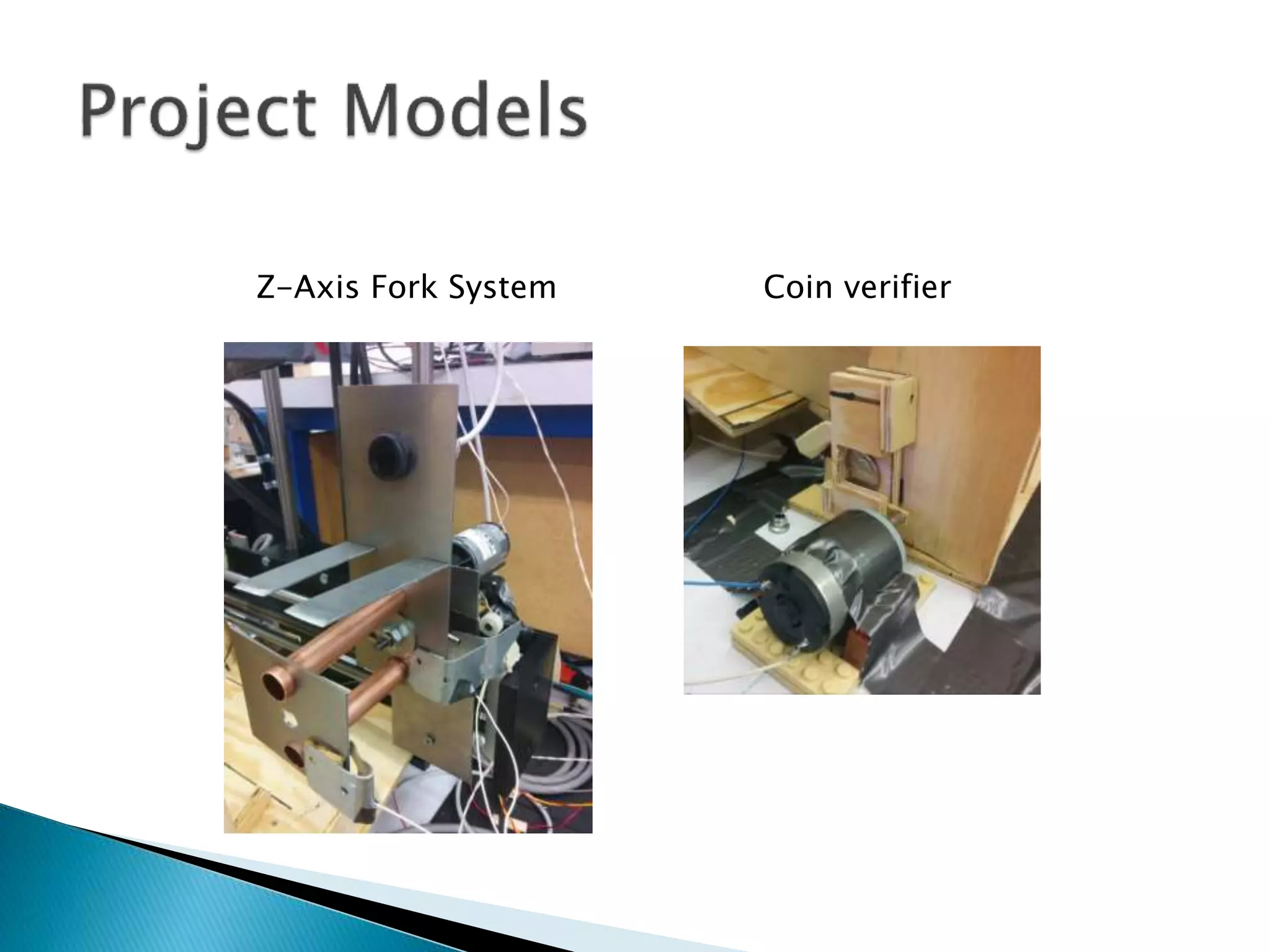

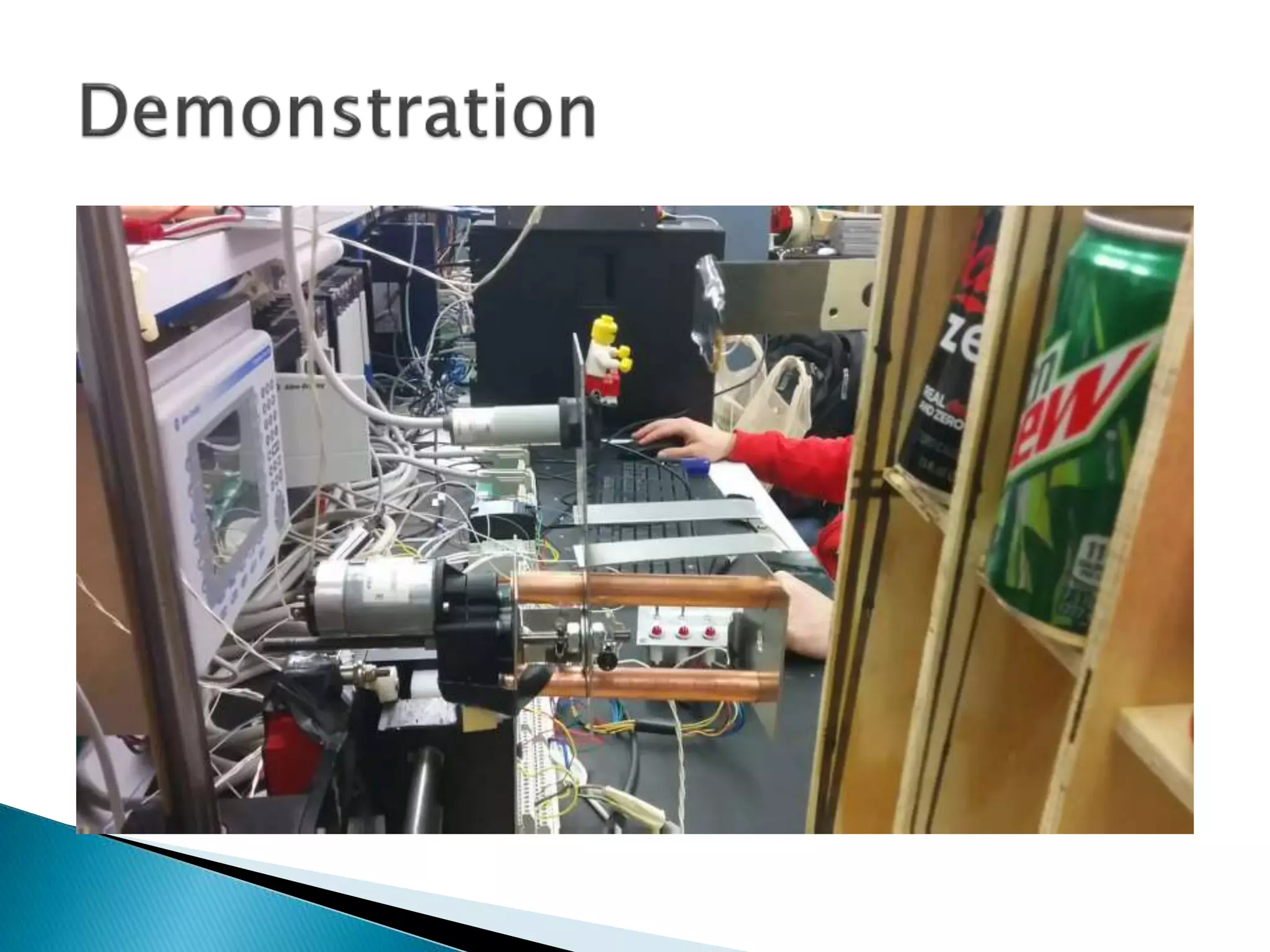

This document outlines the goals, components, procedure, and models for an automated soda vending machine project. The machine will use a 3-axis stage with a fork to pick sodas from stock and drop them in the dispenser. It will check item availability and temperature using LabVIEW. Payment will be made through a coin counter and verified via an Android interface. Components include motors, sensors, a cooler, and electronics. The procedure involves a user selecting a soda on the app, inserting payment, and receiving the soda. Questions address improving the first motor, third axis calibration, and adding extra payment options.