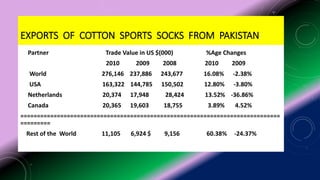

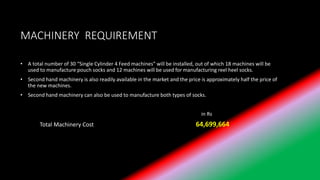

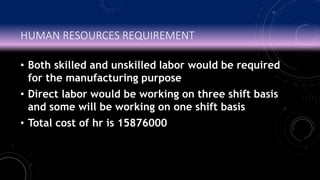

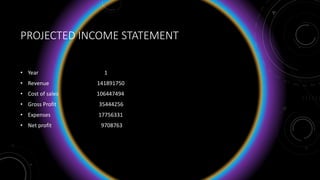

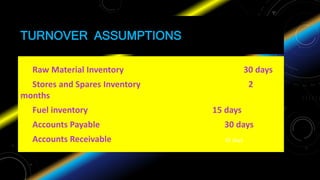

This document summarizes a proposed socks manufacturing project in Pakistan. It discusses SMEDA's role in supporting small businesses, provides an overview of the socks market and production process, lists machinery and other requirements, and presents financial projections showing increasing profits over 10 years. The project requires a Rs. 87.5 million investment and can be financed through 50% equity and 50% bank loans.