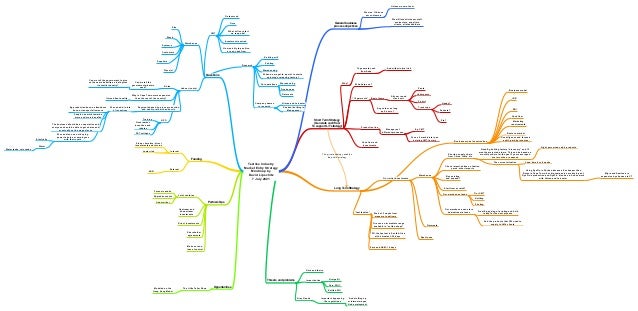

The document outlines a strategic plan for entering the textiles industry, emphasizing both short-term and long-term strategies for cash flow generation and market presence. It explores aspects such as production processes, supply chain management, and the fast fashion model while considering investment opportunities and challenges like import duties and labor costs. The approach includes collaborative business models, potential partnerships, and efforts to incentivize stakeholders for shared benefits.