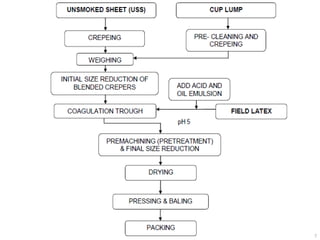

The document discusses the production of SMR GP (general purpose natural rubber), which is a major material for tire production. SMR GP is made from a 60:40 mixture of latex-grade sheet rubber and field coagulum. It is prepared from a blend of latex rubber, unsmoked sheet rubber, field coagulum rubber, and plasticizer. SMR GP production is important for tire manufacturing because its dark color and blending of materials ensure high quality suitable for tires. The document outlines the general properties and composition of SMR GP, as well as the process flow for its production through co-coagulation of latex and wet crumbs.