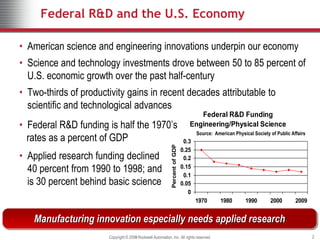

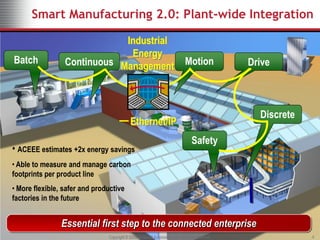

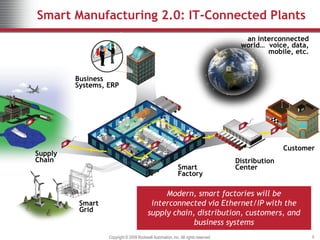

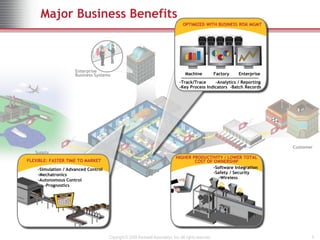

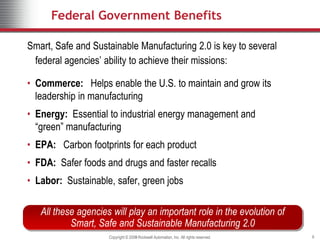

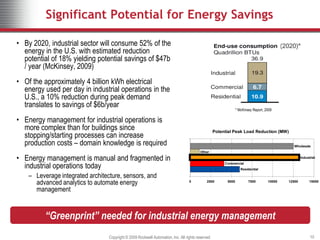

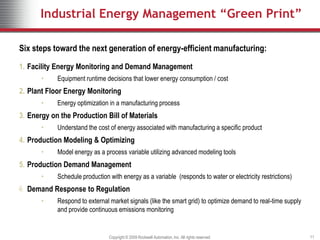

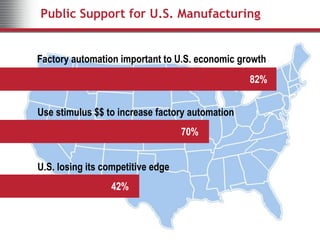

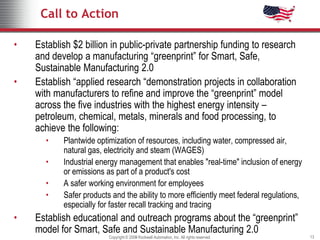

The document discusses the importance of smart, safe, and sustainable manufacturing for the U.S. economy, emphasizing the critical role of federal R&D funding, which has declined over the years. It highlights advancements in manufacturing technologies and energy management strategies aimed at improving efficiency and environmental compliance. The document calls for significant public-private partnerships to establish a 'greenprint' for future manufacturing efforts, focusing on applied research and safer practices.