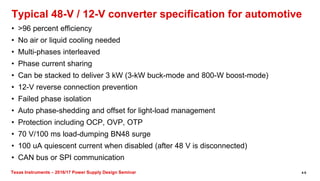

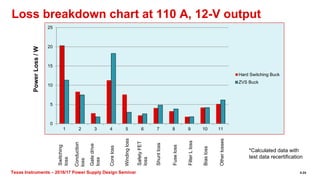

This document summarizes a seminar on bi-directional DC/DC converter topologies for automotive and server applications. It compares a hard-switching fixed frequency buck converter design to a soft-switching zero-voltage switching transition-mode buck converter design. Test results show the soft-switching design has lower switching losses, lower voltage overshoot, and higher efficiency compared to the hard-switching design. The document also discusses control schemes, component selection, and efficiency comparisons between the two designs.