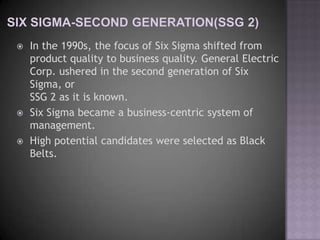

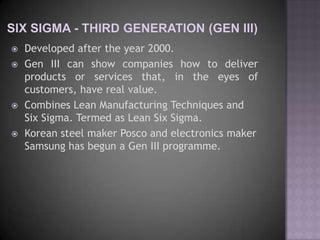

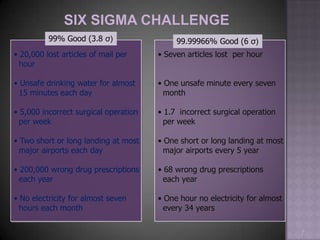

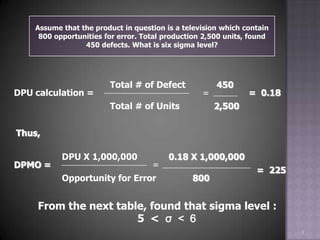

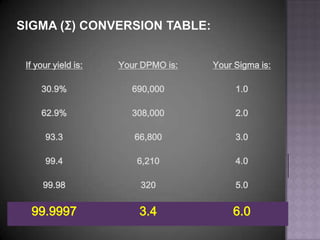

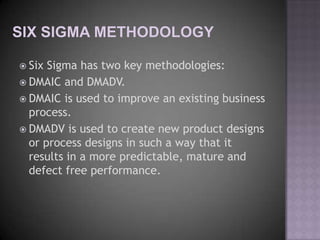

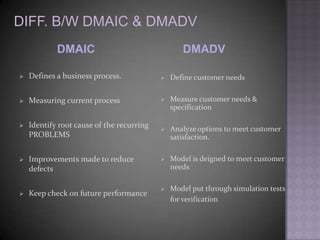

Six sigma methodology was developed by Motorola in 1987 to improve quality and reduce defects. It aims for only 3.4 defects per million opportunities. Six sigma provides statistical tools to analyze processes, identify issues, and implement solutions to improve processes and customer satisfaction while reducing costs. The methodology was later adopted by other companies like General Electric and focuses on both manufacturing and business processes.