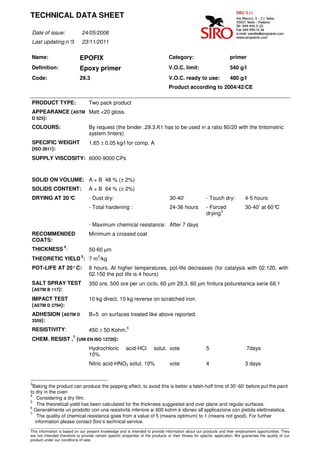

EPOFIX is a two-pack epoxy primer intended for use on iron, aluminum, galvanized iron and light alloys, as well as concrete surfaces. It requires thorough surface preparation through sanding or mechanical cleaning followed by degreasing. The primer consists of Components A and B, which are mixed together prior to application by spray gun, airless sprayer, or by brush/roller for small areas. EPOFIX dries to touch in 4-5 hours at 20°C and achieves full hardness within 24-36 hours. It offers resistance to acids, alkalis and solvents and can be overcoated within 8 hours for optimal adhesion when mixed with Component B.