The document describes the components and design considerations for steam-driven and electric-driven cargo cranes. It details the parts of each type of winch system including gears, clutches, barrels and engines. Equations are provided to calculate key specifications like winch barrel diameter, gear ratios, torque and power requirements based on the load weight and other factors. The goal is to select appropriate dimensions and power sources to safely lift and lower cargo while optimizing efficiency.

![Steam Winch Design

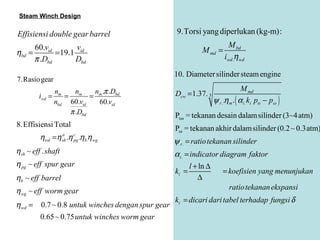

2. Diameter winch barrel (cm) Panjang Keseluruhan Tali

Db = (16.5 ~18).dr L m1 = lm1 = π (D b + d r ).m

Kekuatan putus tali (kg) L m2 = lm1 + lm 2 = π (Db + d r ).m + π (D b + 3d r ).m = π (2D b + 4d r ).m

Rbr = 6.Pg Rrb ≥ K m .Pg . kg L m3 = Lm 2 + lm3 = π (2D b + 4d r ).m + π (D b + 5d r ).m = π (3D b + 9d r ).m

L mz = π (zD b + z 2 .d r ).m

3. Panjang barrel winch (cm)

Memperhitungkan faktor uniformity in arrangement :

Lb = (1.1~1.6) Db

L mz = βb .π .m (D b + 5d r ).m

4.TALI

Jumlah lilittan tali

βb ≈ 0.9

Lb

m=

dr

Panjang Tali pada layer

lm1 = π (D b + d r ).m

lm2 = π [D b + (4d r - d r )].m = π (D b + 3d r ).m

lm3 = π [D b + (6d r - d r )].m = π (D b + 5d r ).m

lmz = π [D b + (2 zd r - d r )].m = π [D b + (2 z −1)d r ].m](https://image.slidesharecdn.com/shipcargohandling-121120031915-phpapp02/85/Ship-cargo-handling-6-320.jpg)