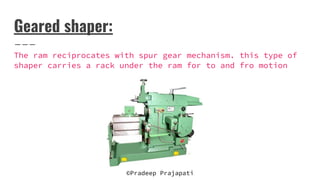

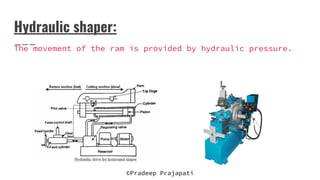

The shaper is a machine tool used primarily for producing flat or planar surfaces that can be horizontal, vertical, or angular. It has a reciprocating ram tool that removes metal from the workpiece during the forward stroke, while the table feeds the workpiece for the next cut on the return stroke. Shapers are classified based on the mechanism driving the ram, whether the ram moves horizontally or vertically, and the design of the table. Common applications include machining horizontal, vertical, and angular surfaces as well as cutting slots, grooves, keysways, irregular surfaces, and gears.