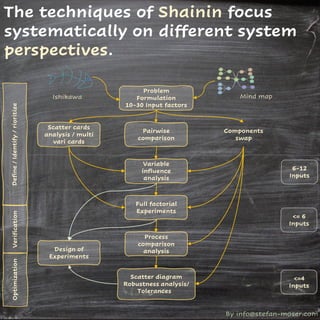

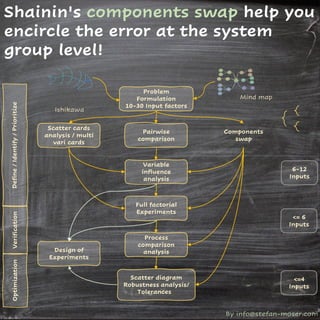

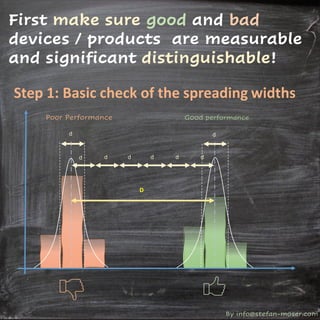

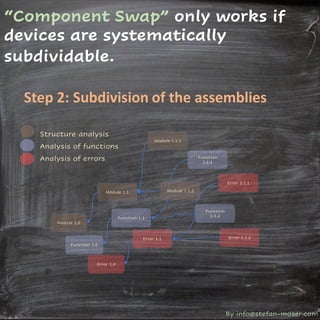

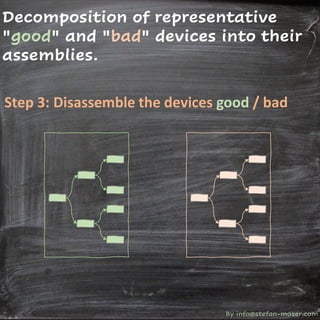

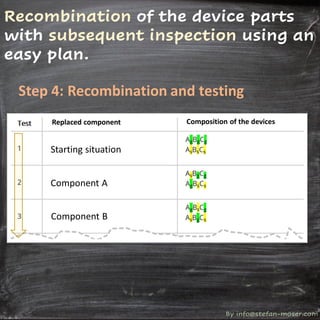

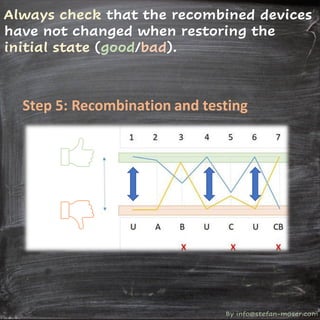

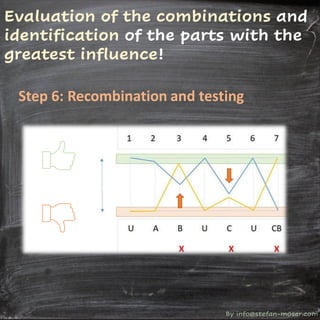

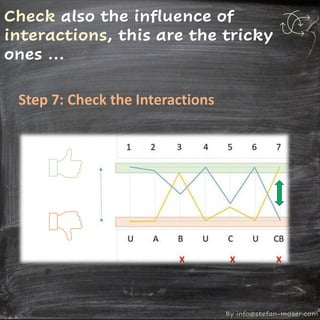

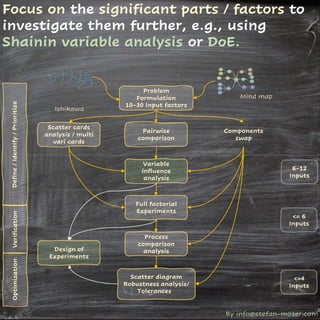

The document describes the technique of component swap analysis to identify the root causes of issues in complex systems. It involves systematically disassembling representative good and bad devices into their components, recombining the components in different configurations, and testing the recombined devices to evaluate the influence of each component and interactions on device performance. The goal is to prioritize the components and factors that most significantly impact the problem for further investigation using techniques like variable analysis or design of experiments.