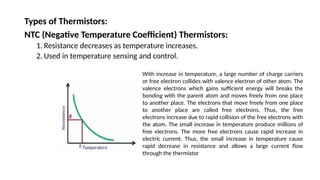

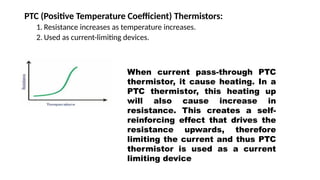

The document discusses sensors and transducers, highlighting their roles in detecting physical inputs and converting them into electrical signals, with examples of application in IoT, industrial automation, and various types of sensors. It details the importance of calibration for accuracy and reliability, explains different sensor types (active vs. passive), and features specific examples such as thermocouples and thermistors for temperature measurement. Additionally, the document outlines the construction and functioning of thermocouples and thermistors, providing insights into their various applications.