1) Jacobs Industries contracted the team to manage their expanding supply chain over two years to maximize cash. The team's strategy generated $21,126,259.82 in cash with $157,825,250 in revenue and a profit of $125.93 per unit.

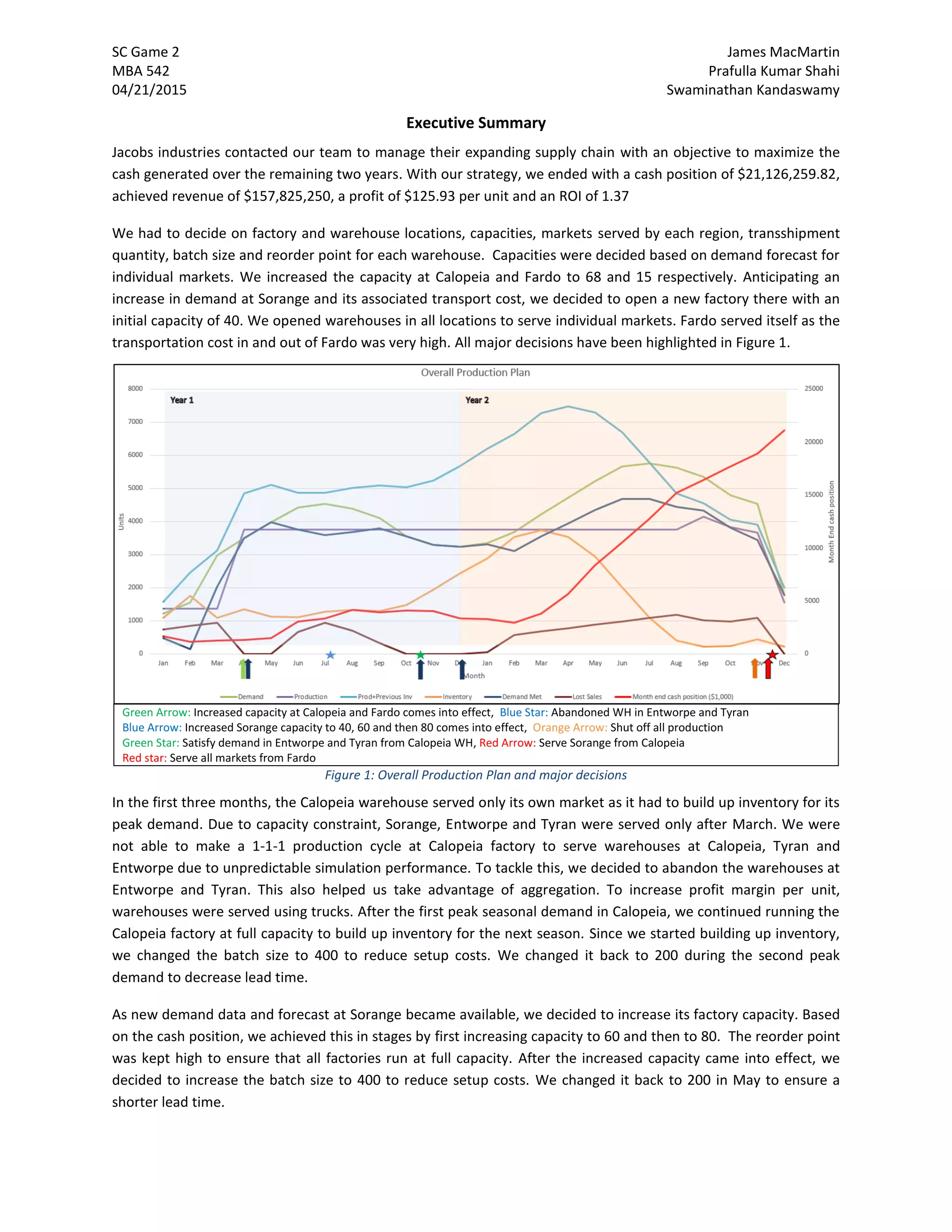

2) The team decided on factory locations and capacities, warehouse locations, markets served, and reorder points. They increased factory capacities in Calopeia and Fardo and opened a new factory in Sorange.

3) To increase profits, the team served warehouses using trucks. They abandoned warehouses in Entworpe and Tyran to take advantage of aggregation and reduce inventory. The team increased Sorange factory capacity over time to meet demand.