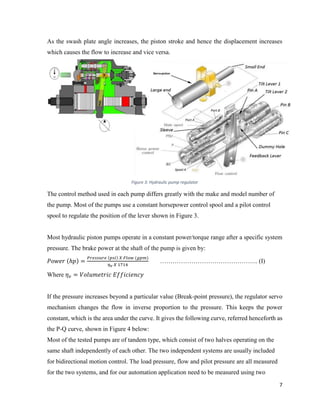

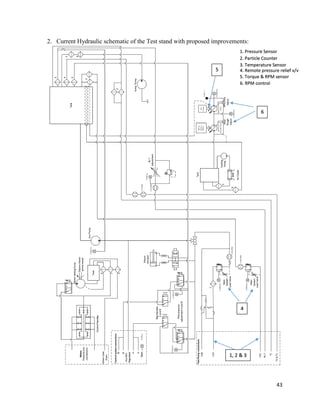

This document describes an internship project to automate the pump testing process at Atlantic Hydraulics in Sanford, NC. The project aimed to reduce testing time and improve data collection. It involved selecting sensors and actuators to automate control of parameters like RPM, pressure, and oil temperature. A data acquisition system and LabView software were used to create automated testing routines and log data. The automation is expected to improve quality, speed, and information management for pump remanufacturing and testing.