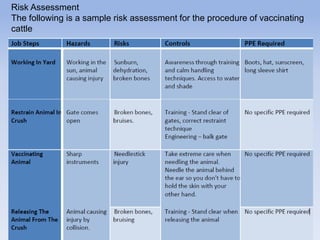

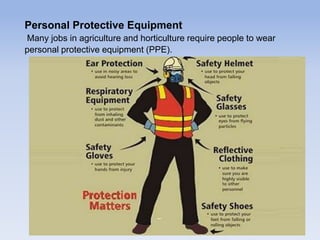

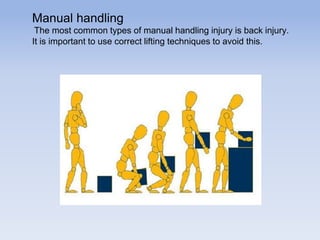

This document discusses workplace safety on farms. It identifies several common hazards on farms like manual handling, animal handling, dust, noise, machinery, and toxic substances. It emphasizes that hazards should be identified, risks assessed and managed through controls like elimination, substitution, engineering controls, procedures, and personal protective equipment. Employers are responsible for safety but workers must also cooperate, receive training, and report any unsafe situations. Standard procedures, emergency plans, and use of protective equipment can help reduce accidents on farms.