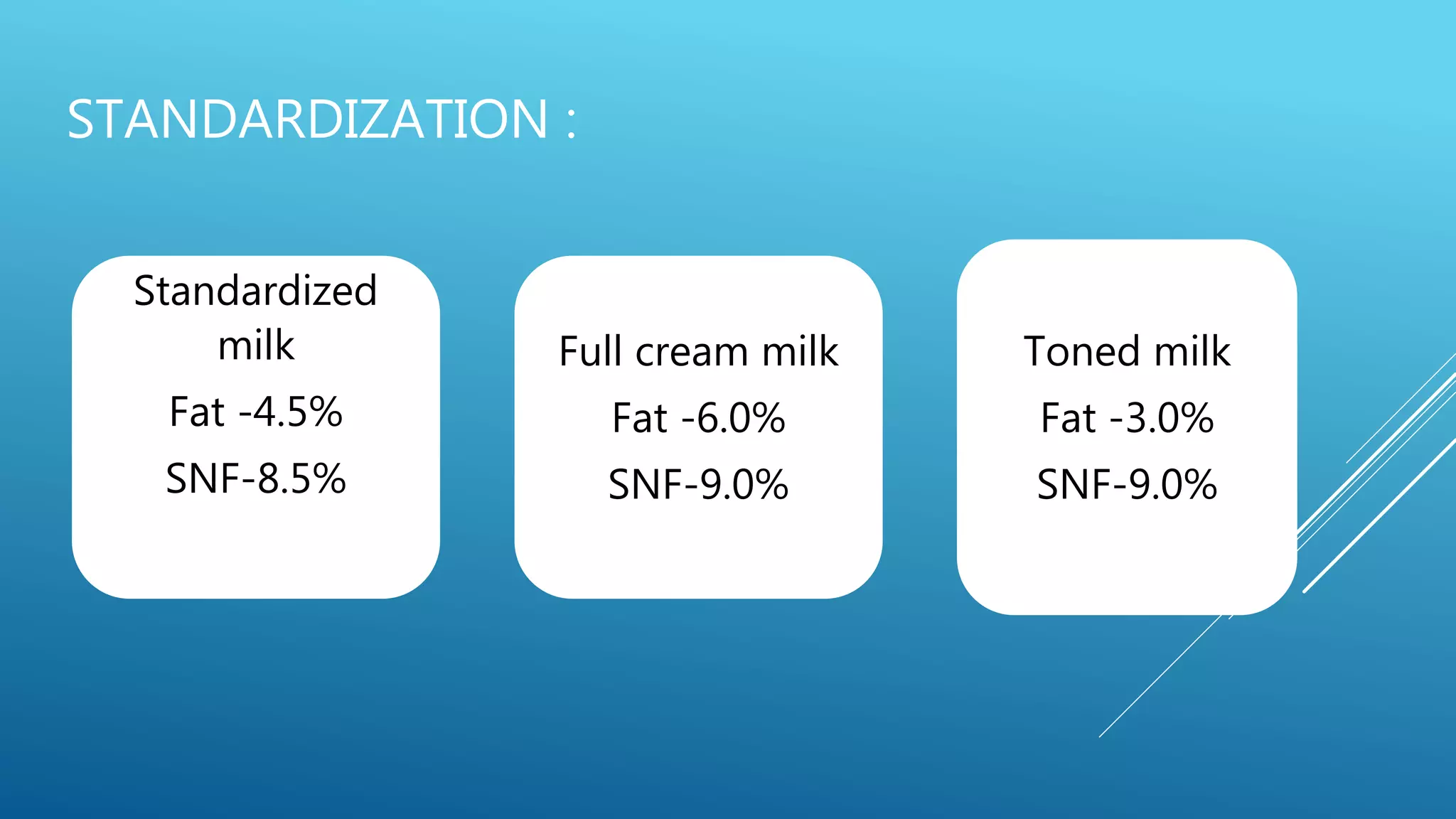

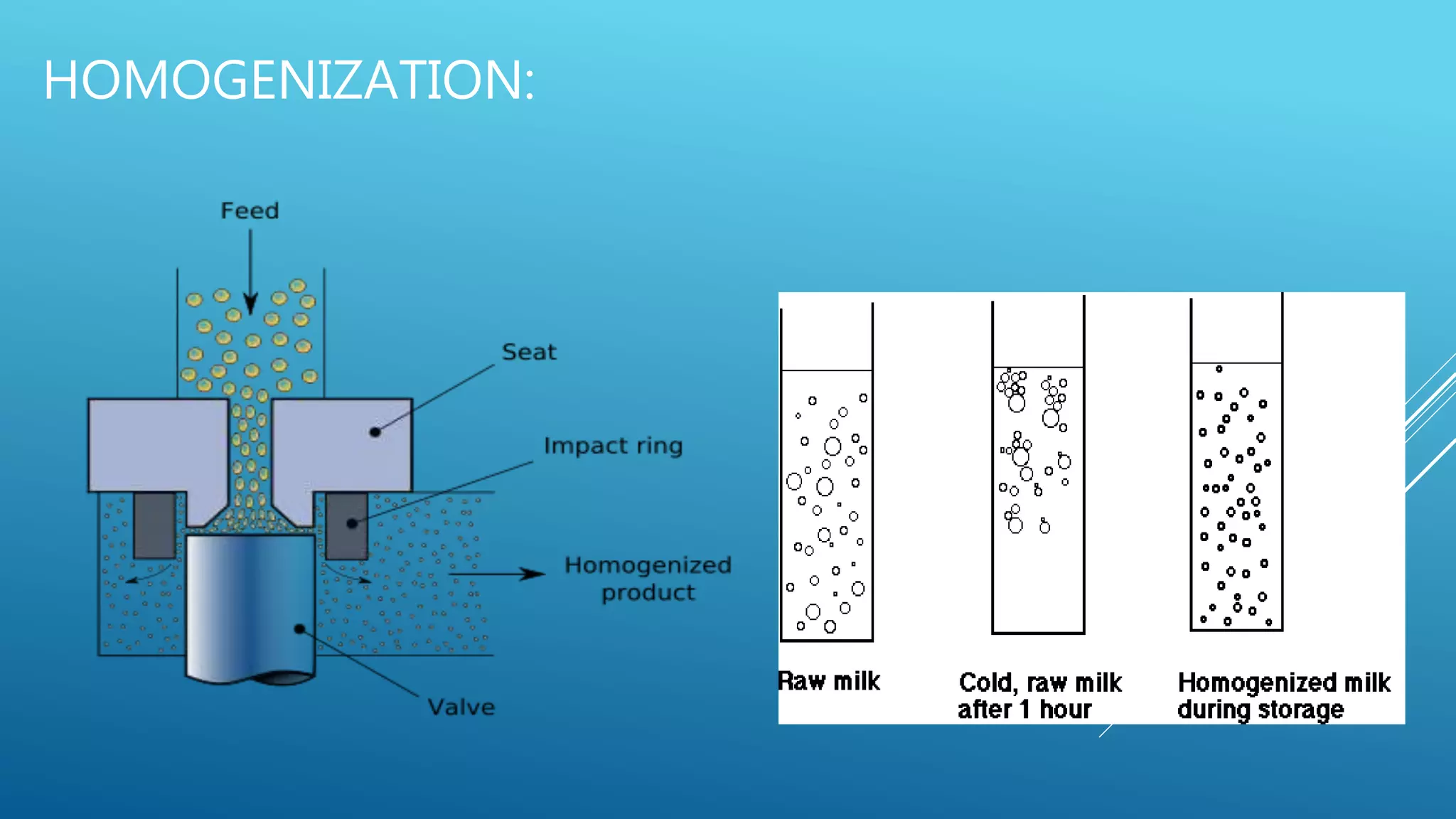

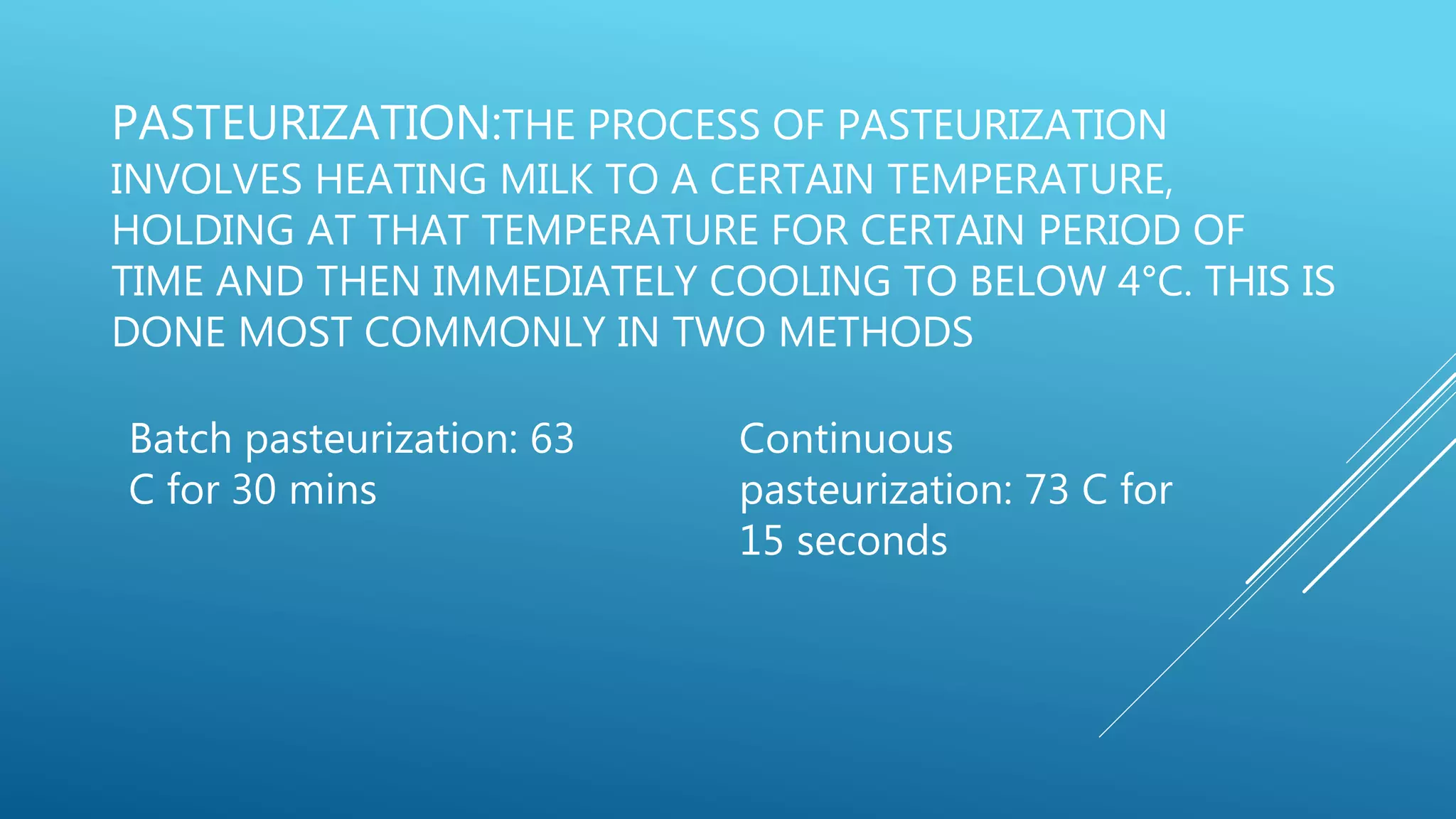

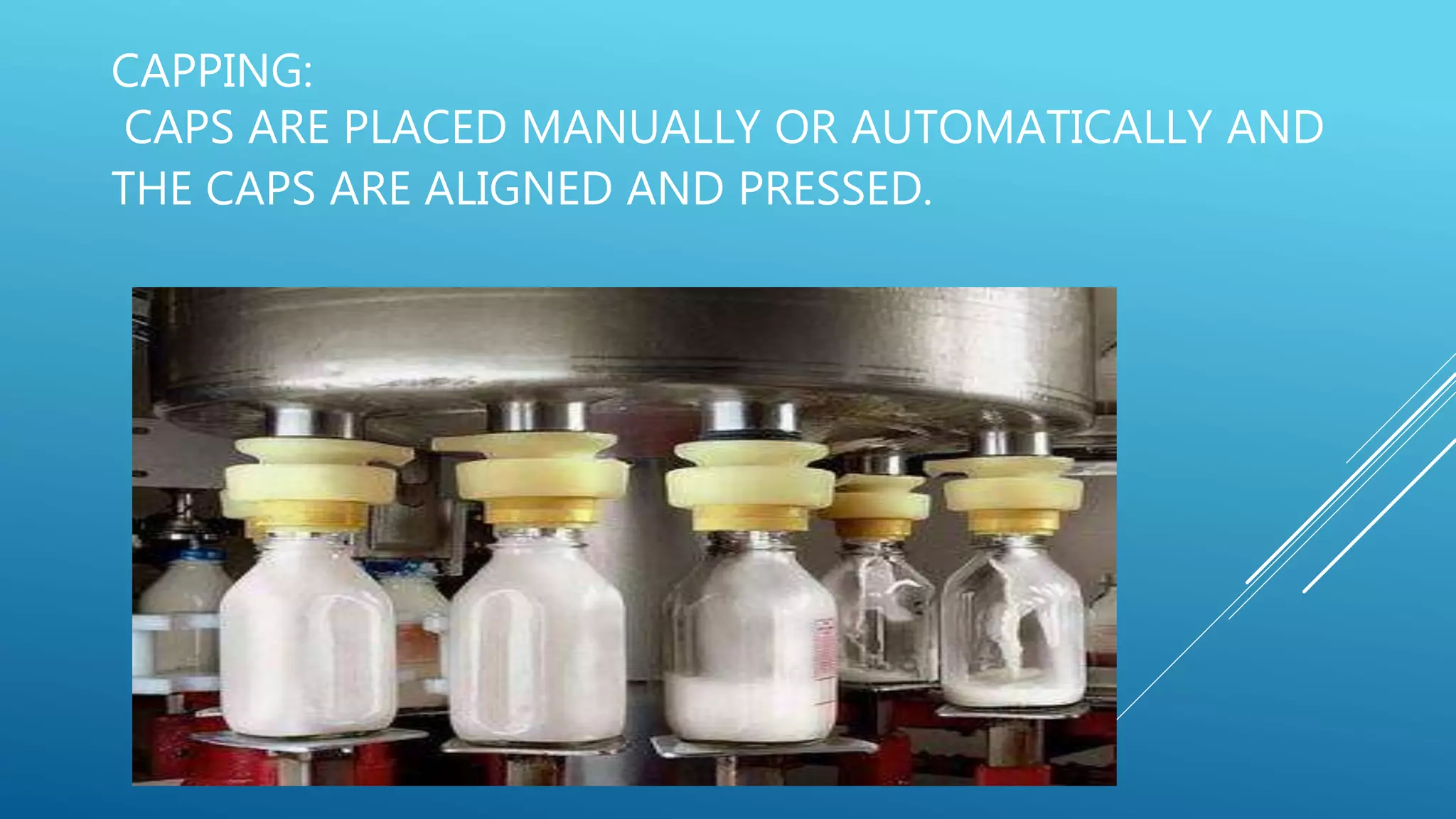

The document summarizes an industrial visit to Ruby Food Products Pvt Ltd, which produces flavored milk products including Jigardanda, Rose, and Badam flavored milks, as well as fruit juices. The processing of almond flavored milk involves standardizing milk to certain fat and SNF levels, homogenizing, pasteurizing, adding almond essence and sugar, filling bottles, capping, retort sterilization, packaging in PET or PP containers, and labeling with required information.