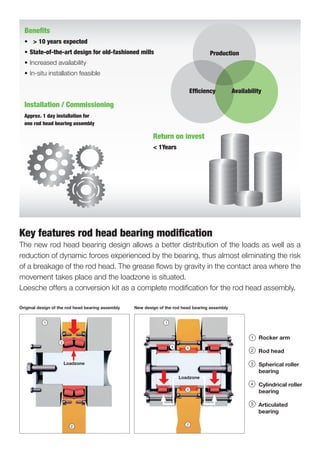

The document discusses a modification to the rod head assembly which improves force distribution at the rocker arms, enhancing performance and reducing the risk of breakage. Loesche offers a conversion kit that allows for in-situ installation, promising a return on investment of less than one year. The modification features a new rod head bearing design that optimizes grease flow and load positioning for better efficiency and longevity.