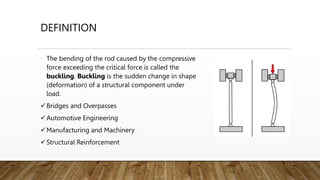

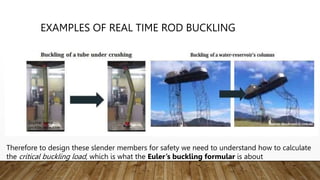

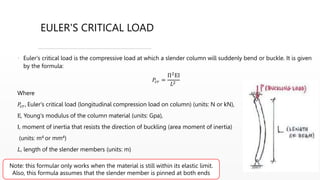

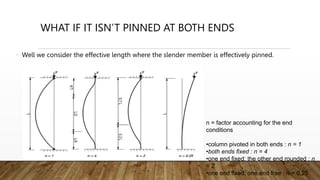

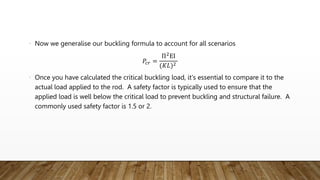

This document defines rod buckling and discusses the fundamentals of calculating the critical buckling load. It explains the different types of equilibrium as stable, neutral, and unstable. Euler's buckling formula for calculating the critical load of a rod is presented, along with modifications to account for different end conditions by using an effective length factor. The importance of ensuring the applied load is below the critical load using a safety factor is also noted to prevent structural failure due to buckling.