This document summarizes Beneq's atomic layer deposition (ALD) equipment portfolio and capabilities for thin film encapsulation and OLED applications. Key points include:

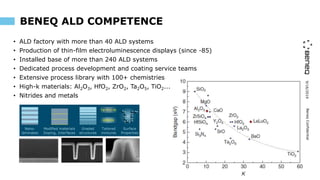

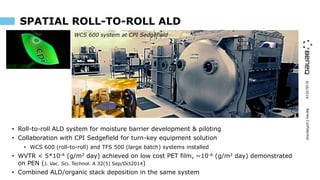

- Beneq is a leading supplier of ALD equipment with over 30 years of experience in applications such as thin film electroluminescence displays and moisture barriers.

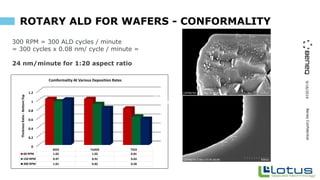

- Their product line includes batch reactors for R&D and production as well as cluster tools optimized for wafer-scale manufacturing.

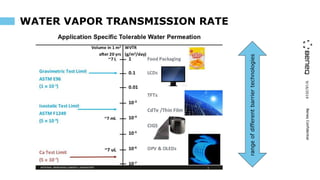

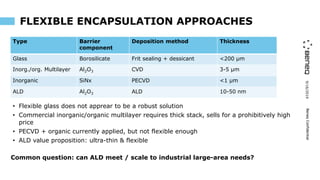

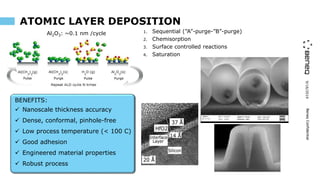

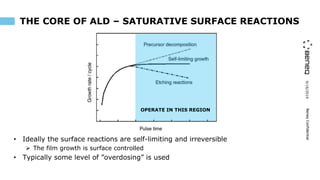

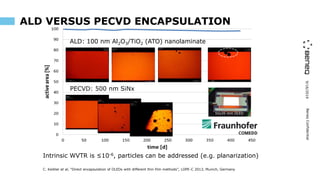

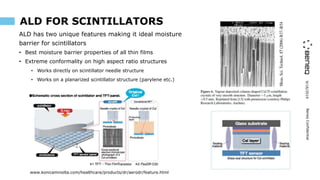

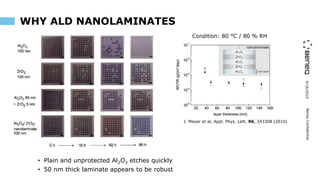

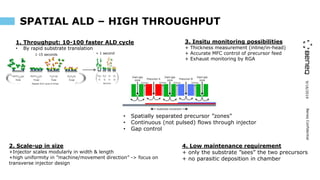

- ALD enables ultra-thin, pinhole-free, and flexible moisture barriers due to its precise thickness control and conformality at low temperatures.

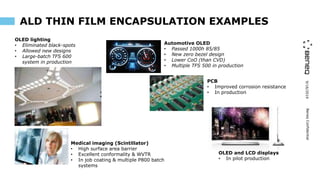

- Beneq has numerous customer references for applications such as medical scintillator encaps