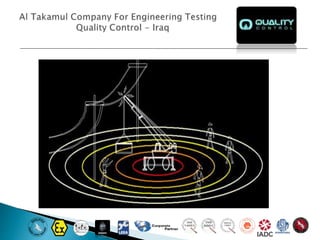

The document provides training information for crane operators, including their responsibilities and safety hazards. It discusses proper inspection and maintenance of cranes, as well as safe operating procedures like ensuring clear communication during lifts, level ground support, and keeping people clear of loads. Hazards mentioned include power lines, overloading, instability, and lack of training or maintenance. Trainees are tested to identify unsafe conditions in images.