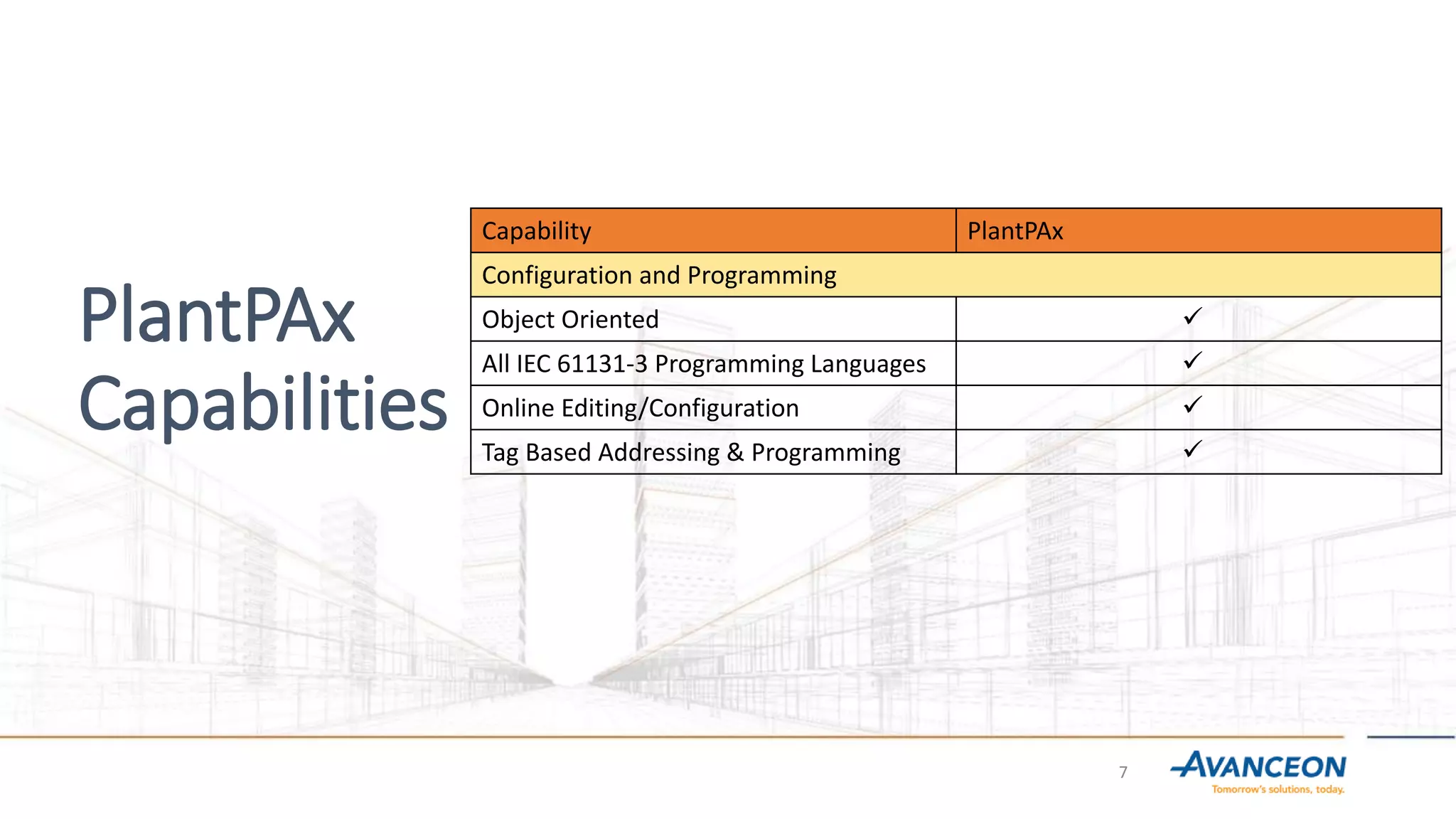

This document provides an overview of the PlantPAx automation system capabilities. PlantPAx is a distributed control system that integrates process and machine control, safety, and information across an entire plant. It uses a modular, scalable architecture and supports all major process control disciplines including continuous, batch, and discrete control. The document outlines PlantPAx capabilities in areas like control system features, configuration and programming, visualization, communications, and advanced process control. It also describes the system's process safety, asset management, batch management, and process optimization functions.

![PlantPAx Process

Networks I/O

Main goal of PlantPAx System

Characterization is:

To provide a recommended

architecture and information

[boundaries] regarding a system

operation and/or performance

early in the sales cycle to reduce

To eliminate perceived risk of the

system being able to provide the

needed performance.

PlantPAx system is carefully tested

and designed to ensure best

possible performance.

Controller Wall

50 + PACs

Distributed System

4 servers

Virtual

System

Centralized

System 1 server

18](https://image.slidesharecdn.com/avanceon-plantpaxprocess-aliomer-160825065825/75/Avanceon-Plant-PAx-Process-18-2048.jpg)