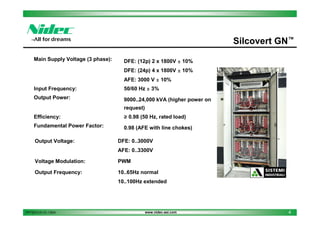

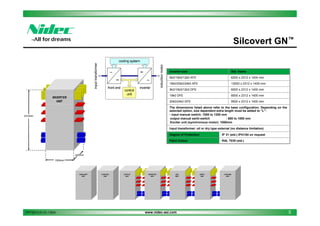

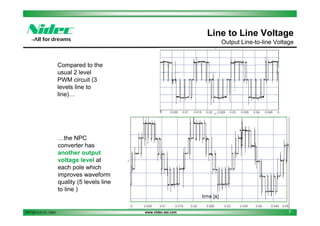

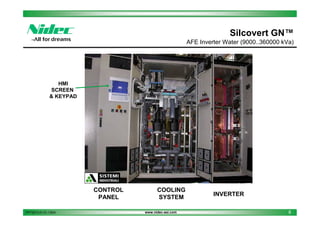

The Silcovert GN is a voltage source inverter using IGCT technology to control large induction and synchronous motors for power ranges up to 24 MVA. It provides high efficiency, power factor, and low harmonic content. A digital control platform provides a user-friendly interface for flexibility in applications. The document provides details on the specifications, components, cooling system, control architecture, HMI, testing facilities, and main applications of the Silcovert GN motor drive.

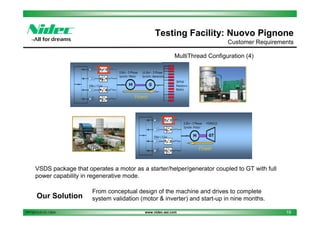

![Testing Facility: Nuovo Pignone

System Performance

Torque Ripple: 2%

Mod.

20-giu-07 Hybrid

Speed

3000

3000

3000

3000

3000

Load

(MW)

6,5

26

29

32

34

Motor in helper

mode

33KV

33KV

Current Voltage

THD%

THD%

7,5

3,0

2,6

3,0

2,5

3,0

2,5

3,0

2,5

3,0

Motor Torque

Torque

[kNm]

19

82

92

102

108

Ripple%

Mech

7,5

4,5

2,5

2,0

2,0

Grid side Current THD = 2,5%

Grid phase current

Mod.

15-giu-07 Asyn.

Speed

1500

2820

3000

3300

3300

3000

PPT2013.01.01.13EN

www.nidec-asi.com

AFE interleaving off AFE interleaving on

Grid

Grid

Grid

Grid

Load Current Voltage Current Voltage

(MW) THD%

THD%

THD%

THD%

5

26,0

13,0

9,0

3,0

21

7,0

13,0

3,0

3,0

21

7,0

13,0

3,0

3,0

20

6,5

13,0

3,0

3,0

27

5,5

13,0

2,5

3,0

27

5,5

13,0

2,5

3,0

20](https://image.slidesharecdn.com/nidecasisilcovertgn-131208203513-phpapp02/85/Nidec-asi-silcovert-gn-20-320.jpg)