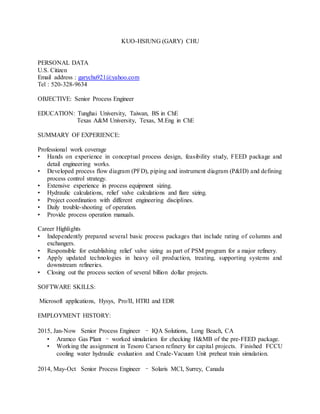

Gary Chu has over 30 years of experience in process engineering. He has worked on numerous projects around the world, holding senior process engineering roles. His experience includes conceptual design, FEED packages, detailed engineering, equipment sizing, process control strategies, and project management. He is proficient in software such as Hysys, Pro/II, HTRI, and Microsoft applications.