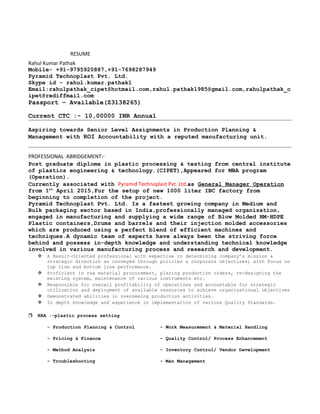

Rahul Kumar Pathak is a General Manager of Operations with over 10 years of experience in plastic production planning and management. He is currently managing operations at Pyramid Technoplast Pvt. Ltd., including setting up a new IBC factory. Pathak has expertise in production management, process enhancement, quality assurance, and resource management. He holds a post-graduate diploma in plastic processing and testing and pursued an MBA.