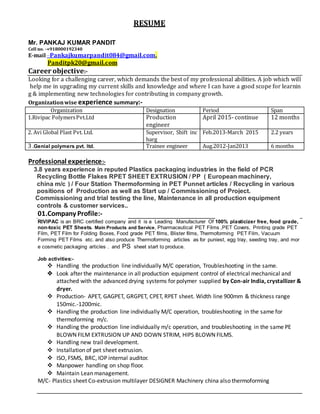

- Pankaj Kumar Pandit is seeking a challenging career that allows him to upgrade his skills and contribute to company growth.

- He has over 3.8 years of experience in plastics packaging industries working in positions of production and commissioning projects.

- His experience includes working with PET sheet extrusion lines, thermoforming machines, and film extrusion equipment.

- He holds a diploma in plastics technology and has undergone training in topics like SPC, FMEA, and BRC.