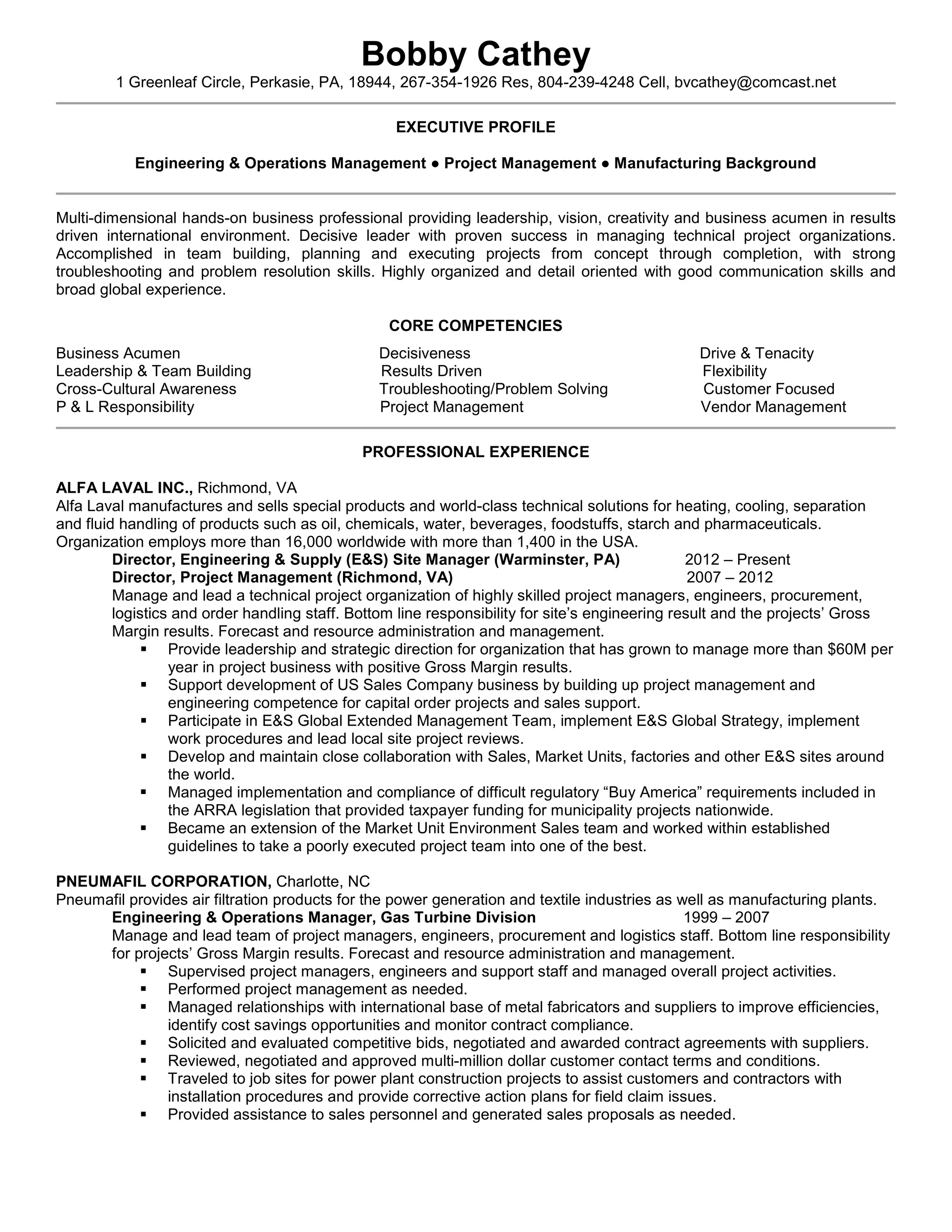

Bobby Cathey is an engineering and operations management professional with over 30 years of experience leading technical projects and organizations. He currently serves as the Director of Engineering & Supply Site Manager for Alfa Laval Inc., where he manages a team that oversees over $60M in annual project business. Prior to this role, he held several director and manager positions with responsibilities including project management, engineering, manufacturing, and operations. Cathey has a proven track record of managing complex global projects, building high-performing teams, and delivering results for organizations in various industries.