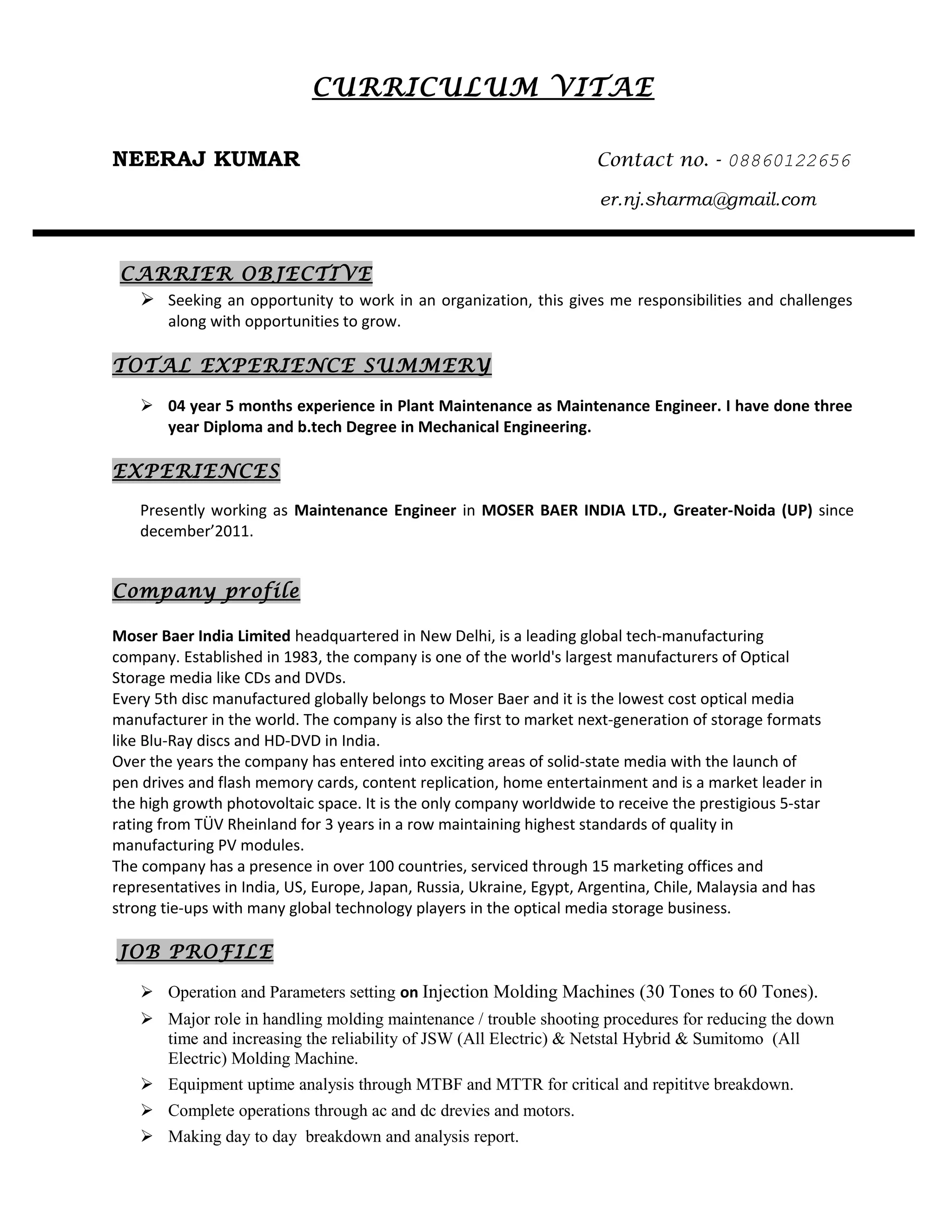

Neeraj Kumar has over 4 years of experience as a Maintenance Engineer. He currently works for Moser Baer India Ltd, a leading manufacturer of optical storage media. In his role, he is responsible for operation and parameter setting on injection molding machines, handling maintenance and troubleshooting to reduce downtime. He also coordinates with various departments to ensure smooth operations and achieve production goals. Neeraj holds a diploma and bachelor's degree in mechanical engineering and provides details of his educational qualifications, computer skills, expected salary and personal details in his curriculum vitae.