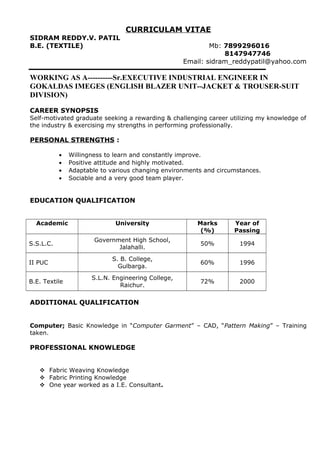

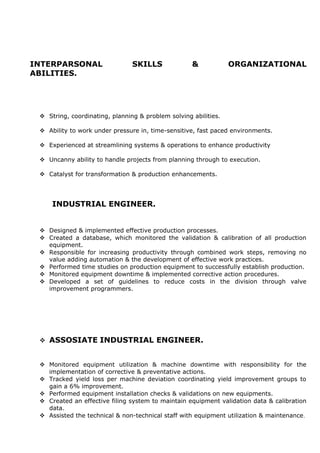

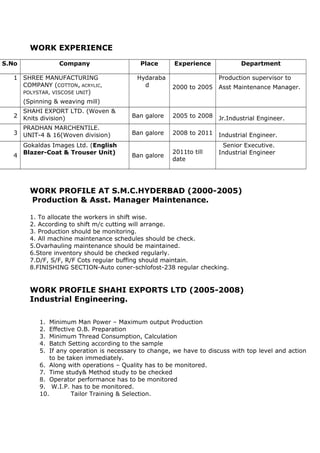

This document is a curriculum vitae for Sidram Reddy V Patil that summarizes his professional experience and qualifications. It outlines his education including a B.E. in Textile Engineering, over 15 years of experience in industrial engineering roles for various textile companies, and his responsibilities like production planning and improving efficiency. It also lists his personal details and strengths like adaptability, teamwork, and a willingness to learn.