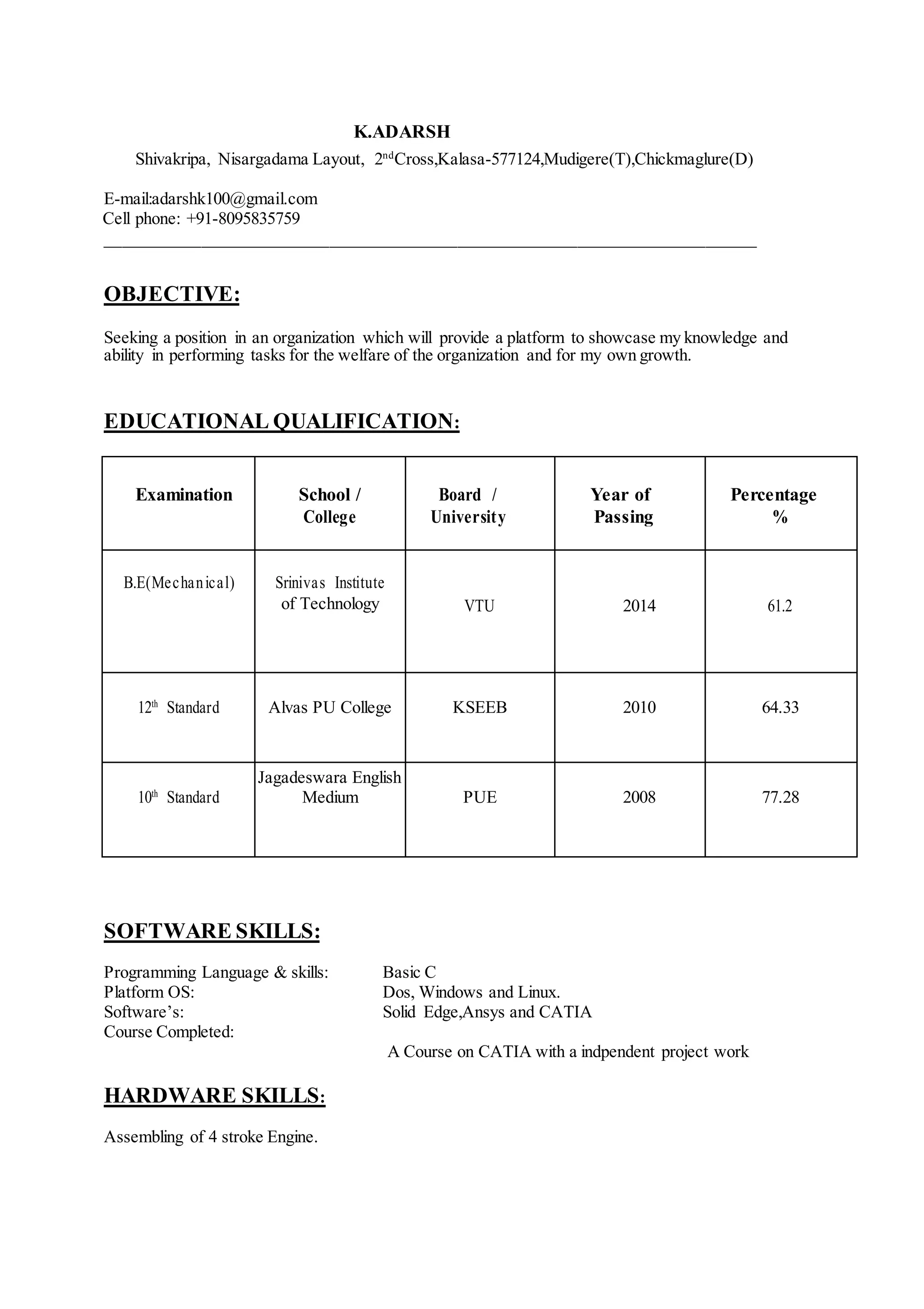

K. Adarsh is seeking a position that allows him to utilize his knowledge and skills. He has a B.E. in Mechanical Engineering from Srinivas Institute of Technology. His skills include programming in C, using CAD software like Solid Edge and CATIA, and assembling engines. He completed projects on a six-stroke engine and robotics. Adarsh worked as a Quality Engineer and Quality Incharge at automotive component manufacturing companies, handling tasks like inspection, calibration, complaint resolution, and documentation. He is looking to contribute to an organization's growth through his qualifications and industrial experience.