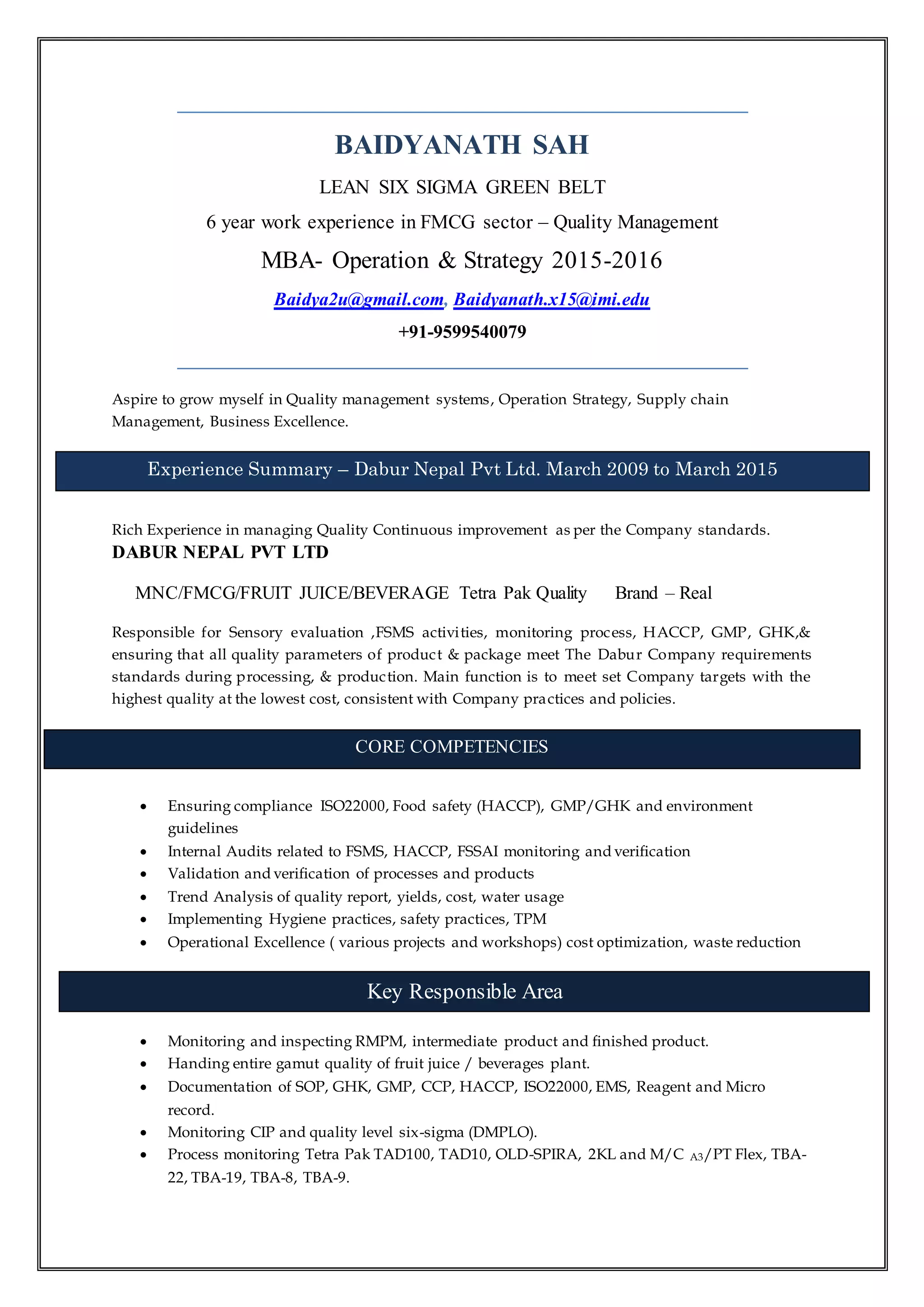

Baidyanath Sah has 6 years of experience in quality management for the FMCG sector. He holds an MBA in Operations and Strategy and is a Lean Six Sigma Green Belt. At Dabur Nepal Pvt Ltd, he was responsible for quality assurance activities including sensory evaluation, HACCP, GMP compliance and ensuring products met quality standards. His experience includes quality audits, process validation, data analysis, hygiene monitoring and documentation. He is proficient in microbiological and chemical testing, effluent analysis, equipment calibration and HACCP verification.