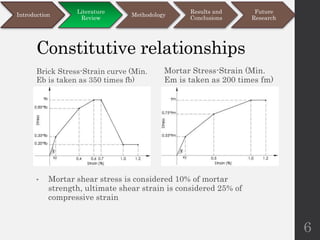

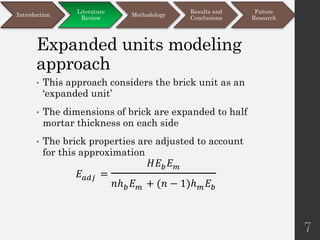

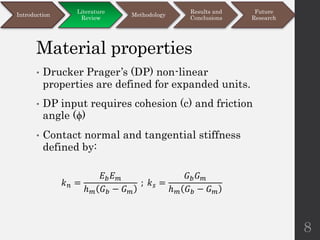

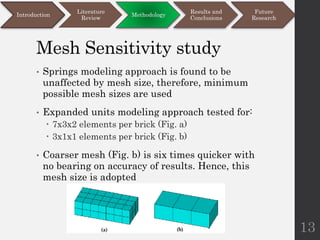

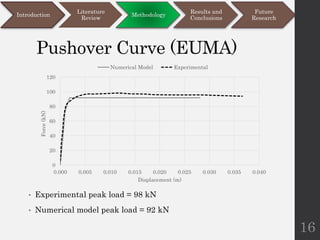

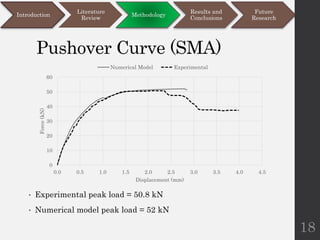

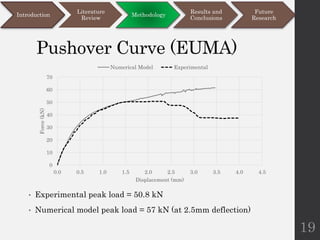

This document discusses different modeling approaches for finite element analysis of masonry structures. It compares the springs modeling approach and expanded units modeling approach by applying them to numerically model and analyze the behavior of four experimental masonry walls under various static and pseudo-dynamic loading conditions. Both approaches are able to predict the load capacities of the walls with reasonable accuracy compared to experimental data, but the expanded units approach is found to be more versatile and accurate. The document also outlines future research directions around improving the accuracy and capabilities of the modeling approaches.