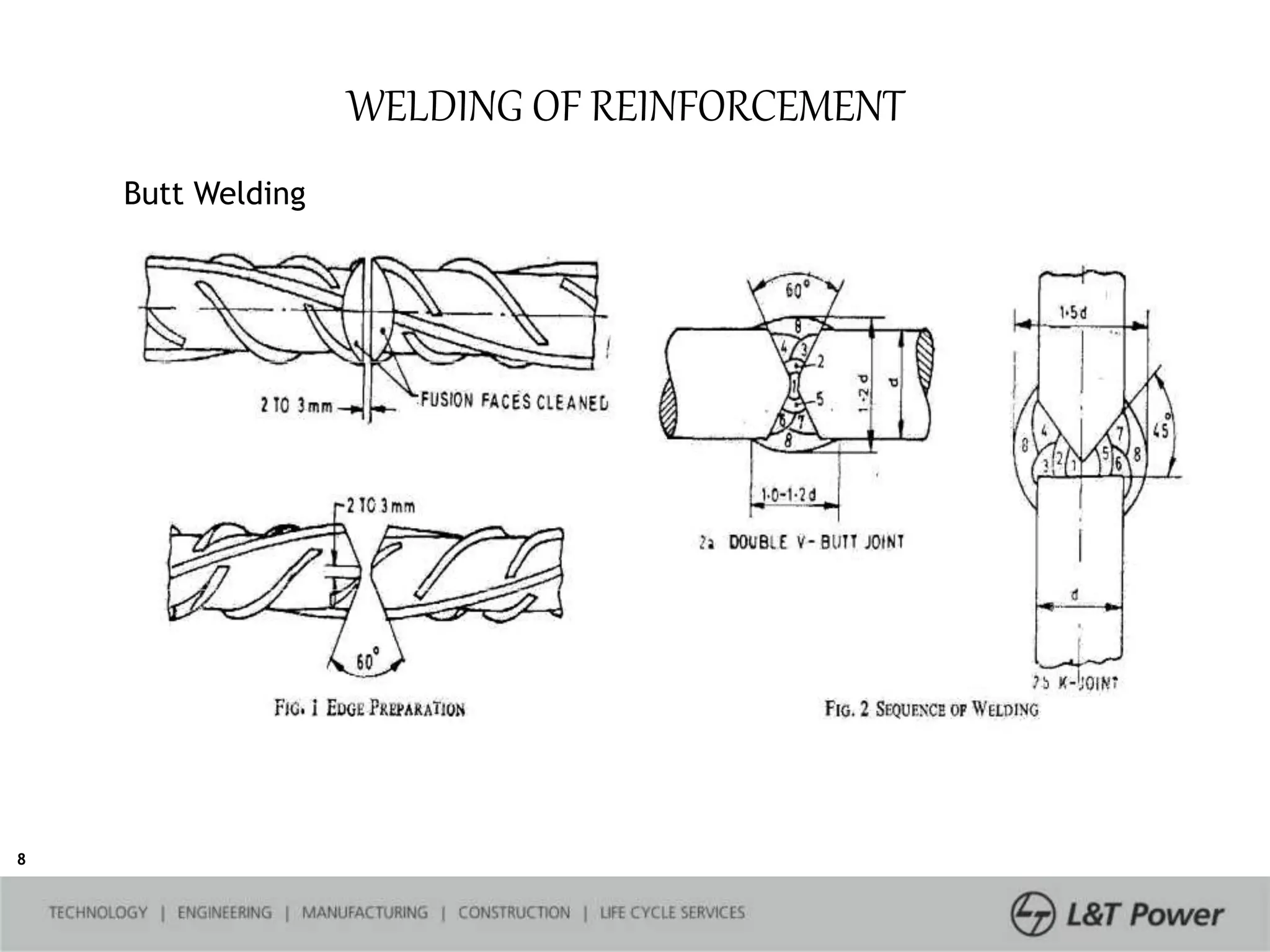

Welding of reinforcement bars is allowed according to IS 1786, provided the carbon equivalent of the steel is below specified limits to ensure good weldability. The welding process used must follow codes like IS 9417 and IS 814. Butt welding or lap welding can be used, employing techniques like shielded metal arc welding, flash butt welding, or gas pressure welding. Quality is ensured through tests like tensile tests and bend tests of welded samples. Precautions like avoiding flame cutting and maintaining minimum bend radii must be followed to preserve the steel's strength properties.