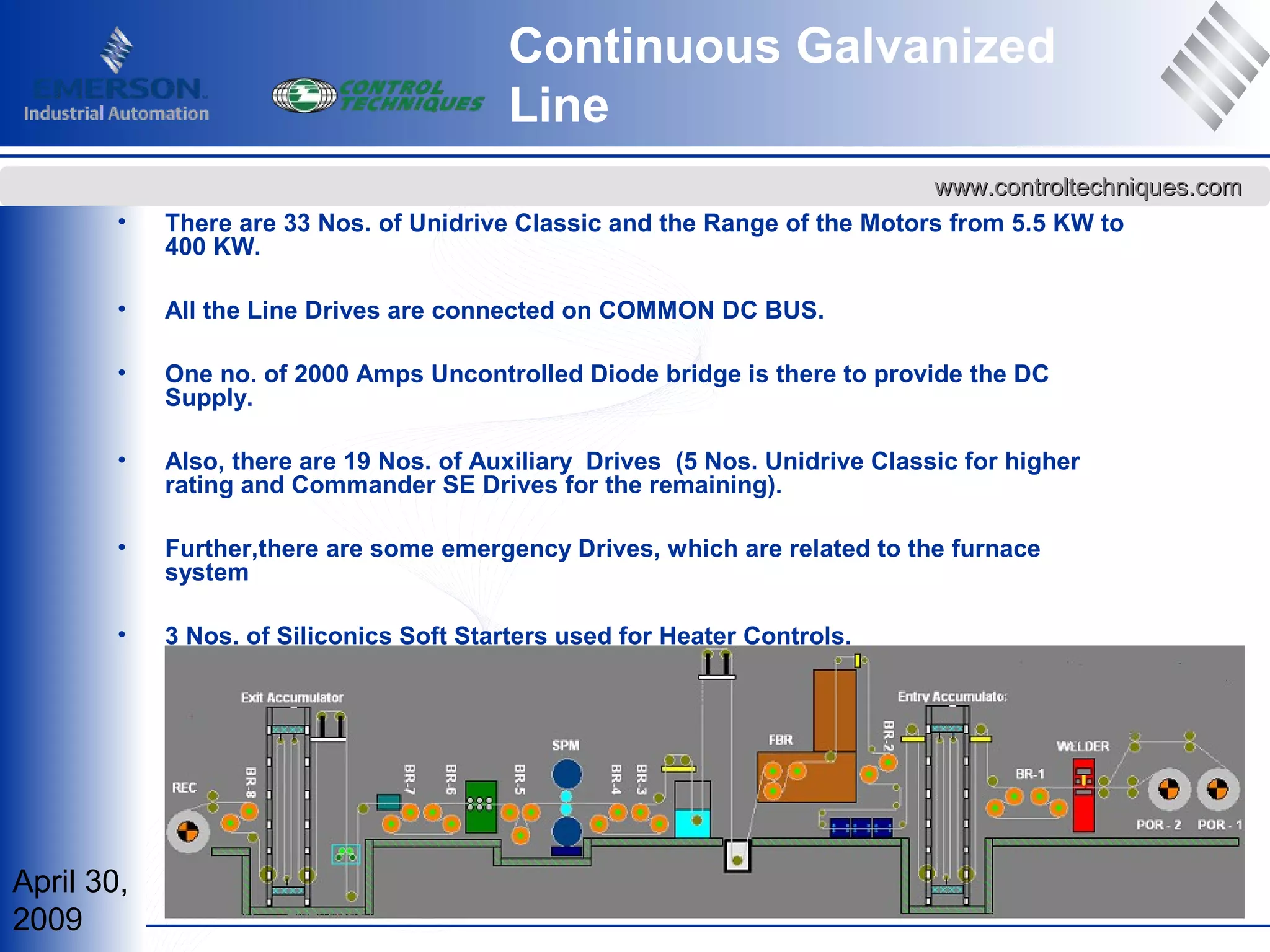

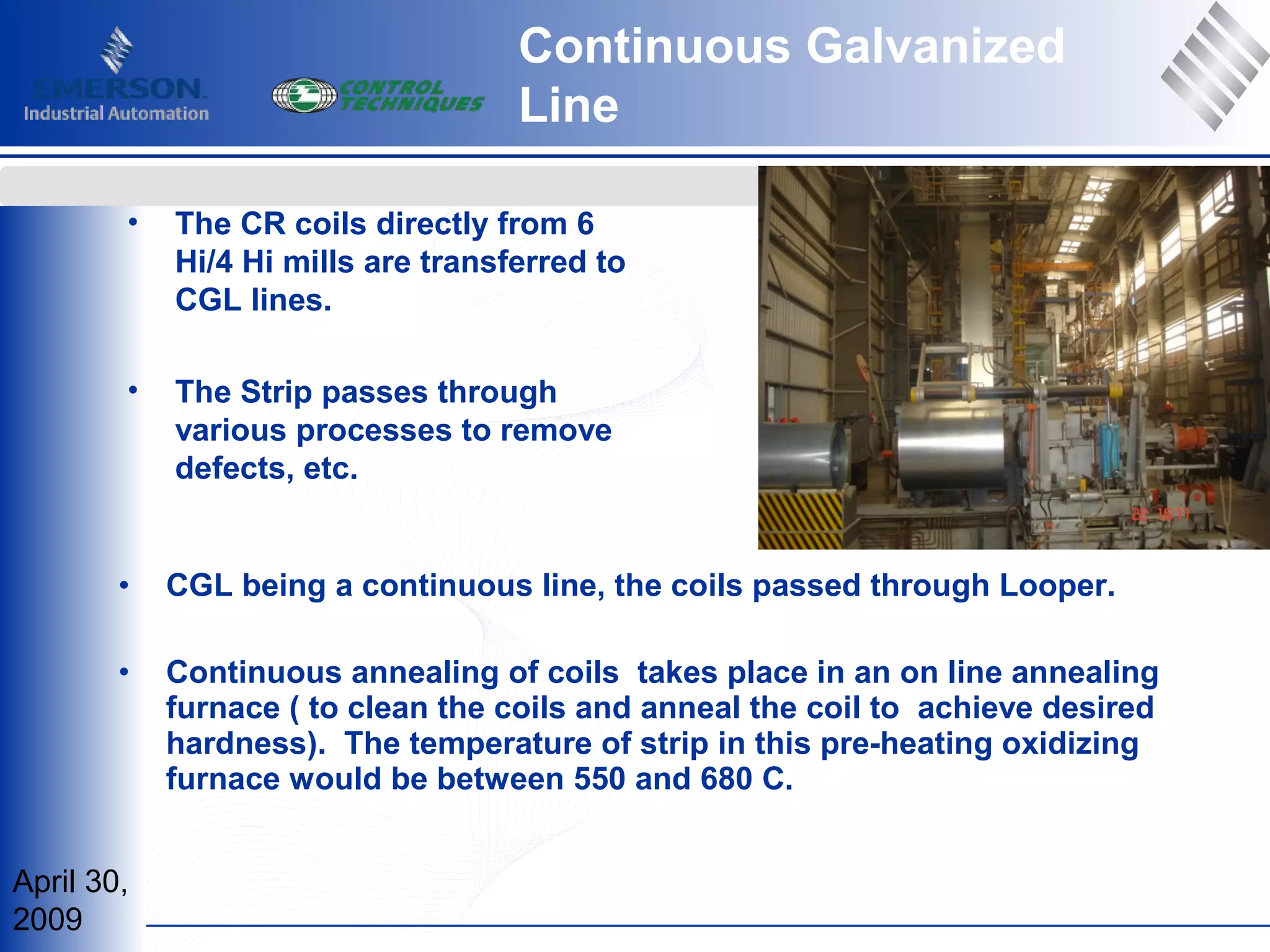

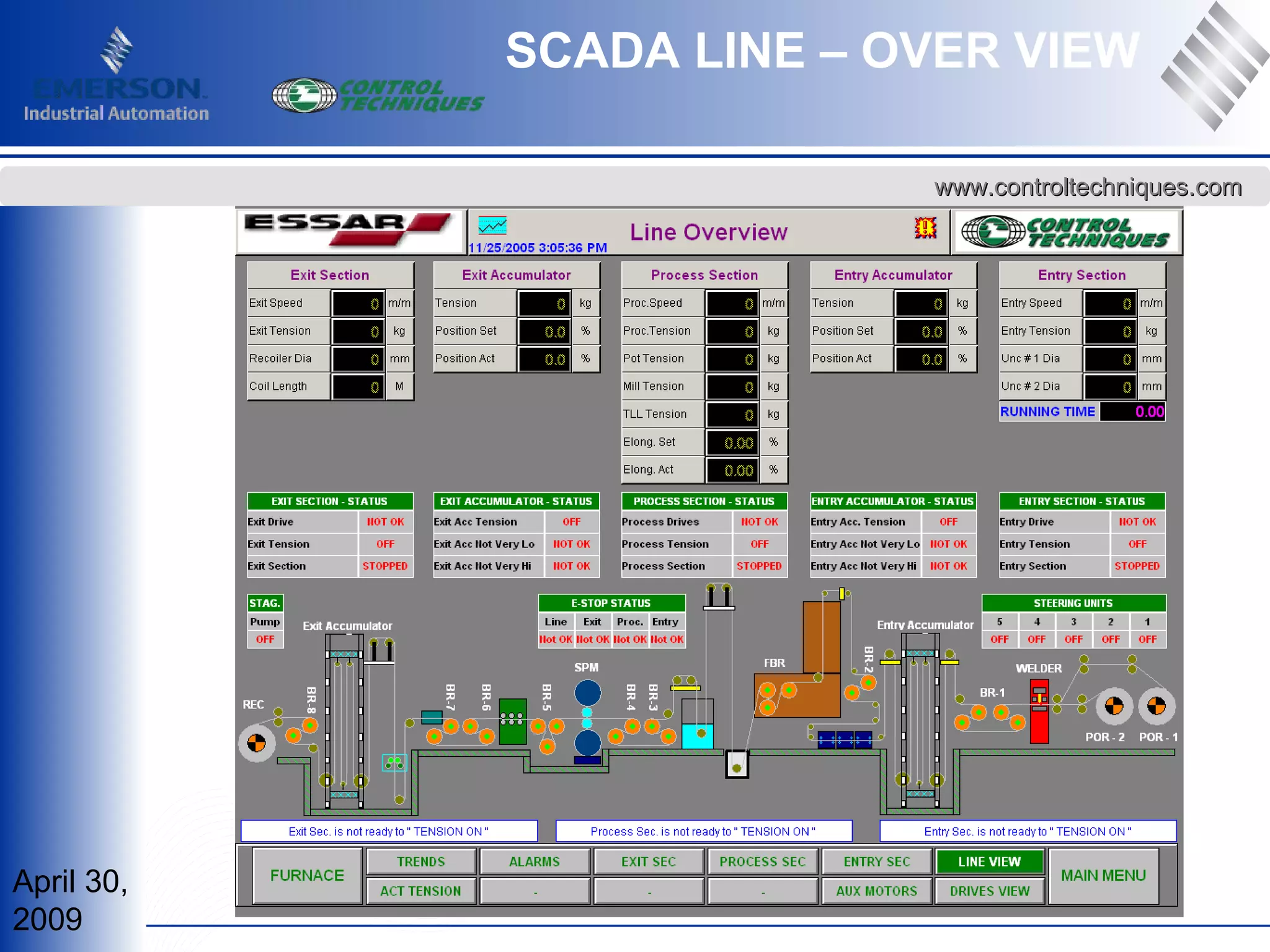

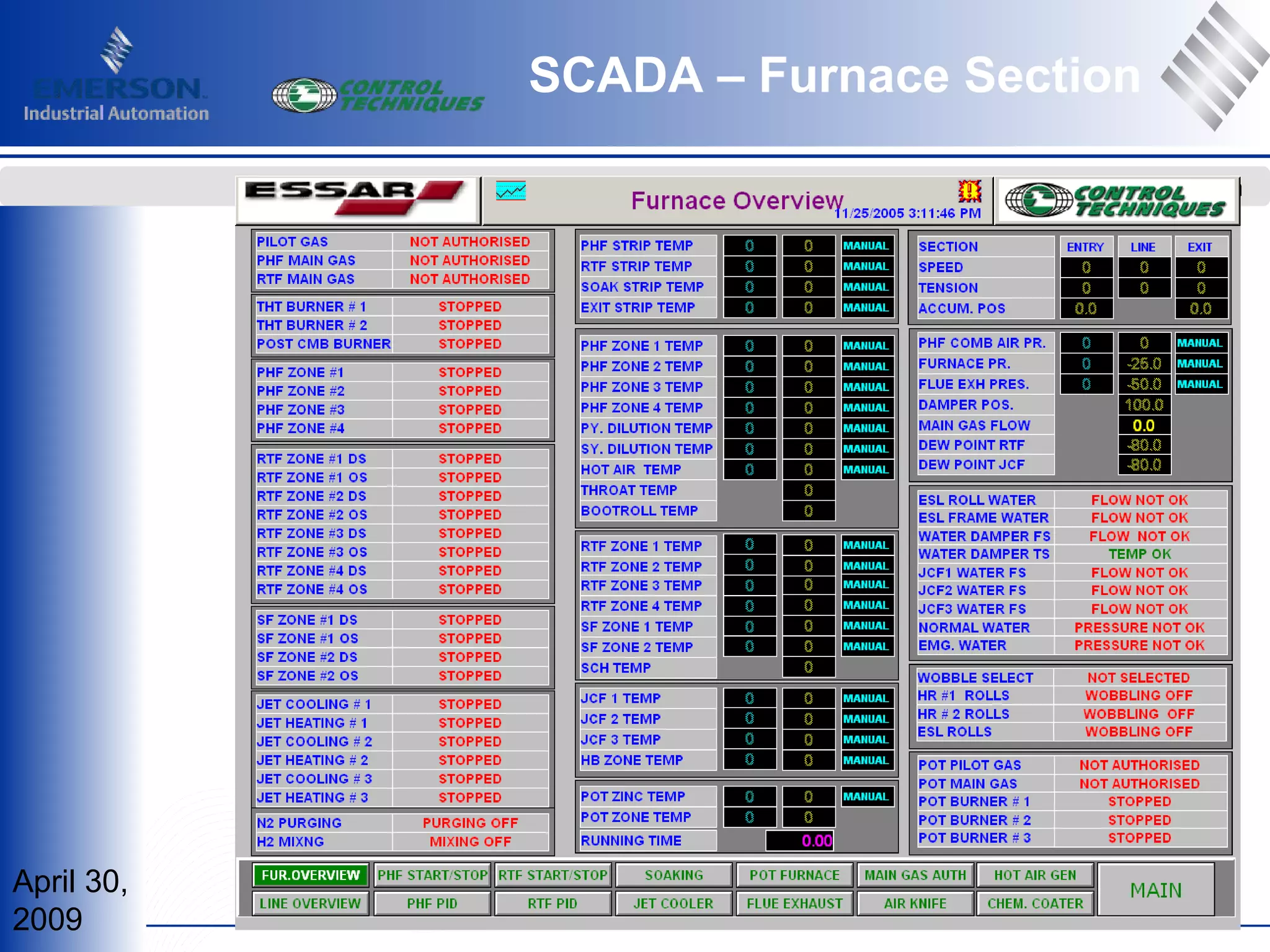

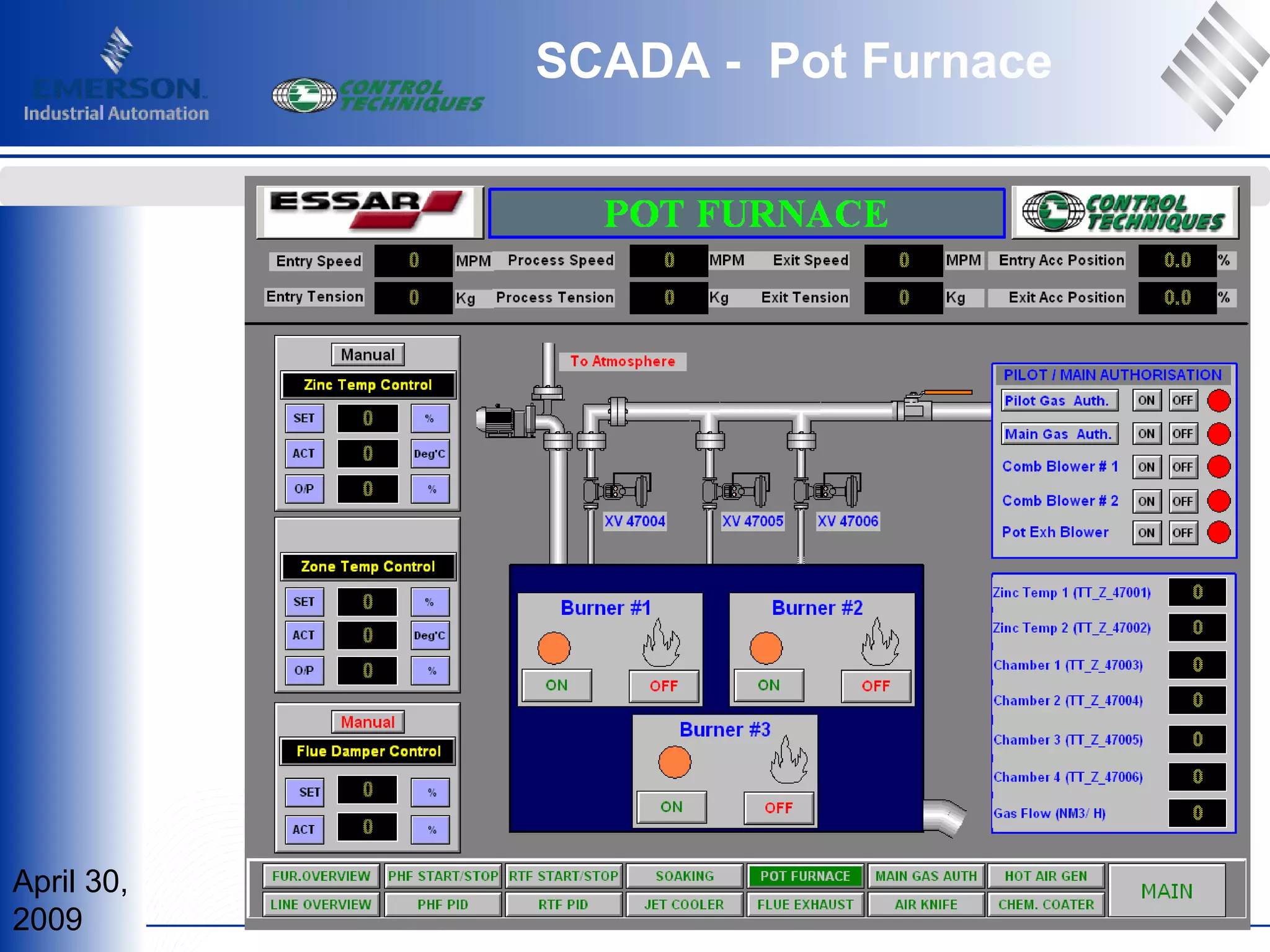

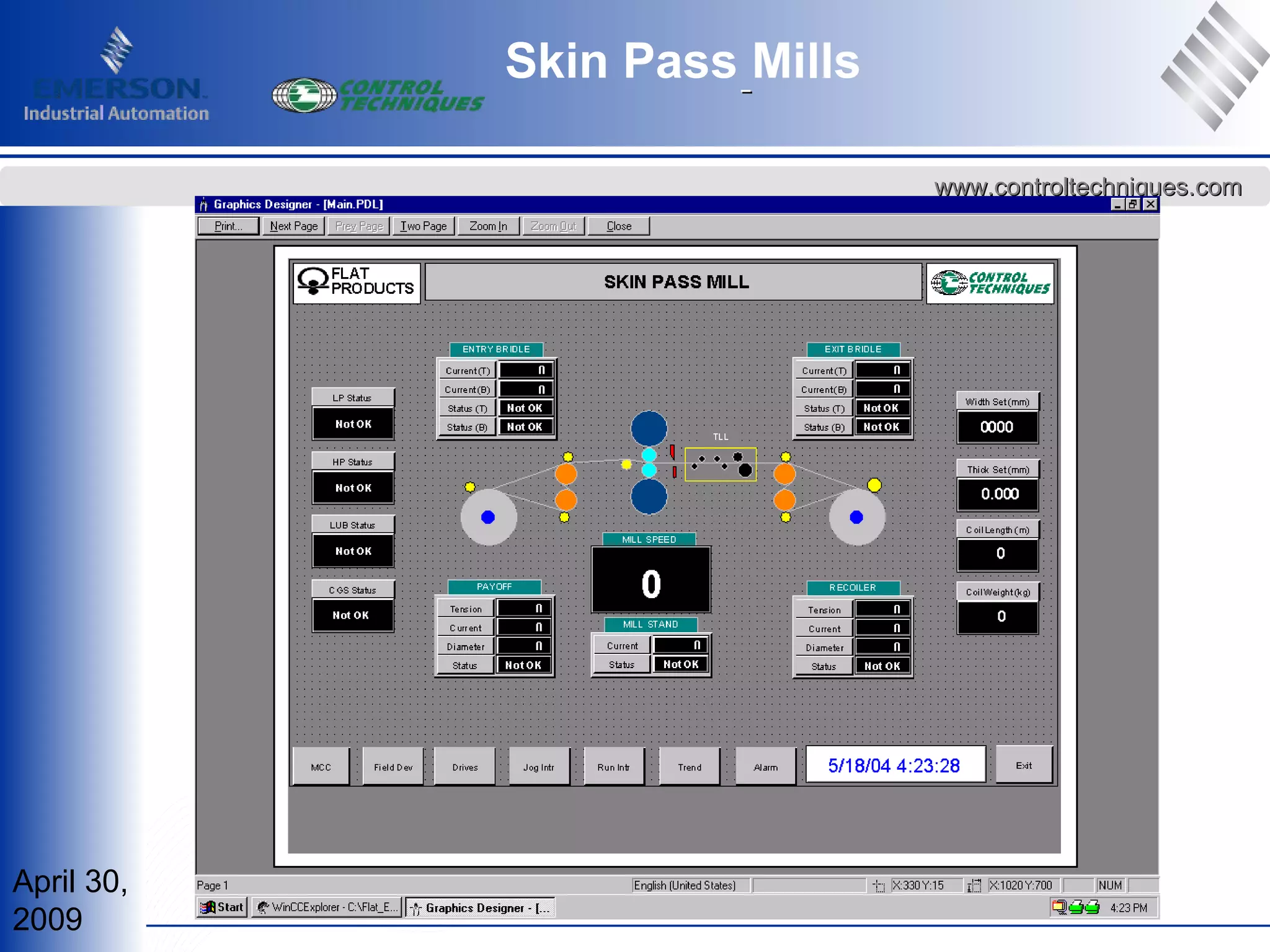

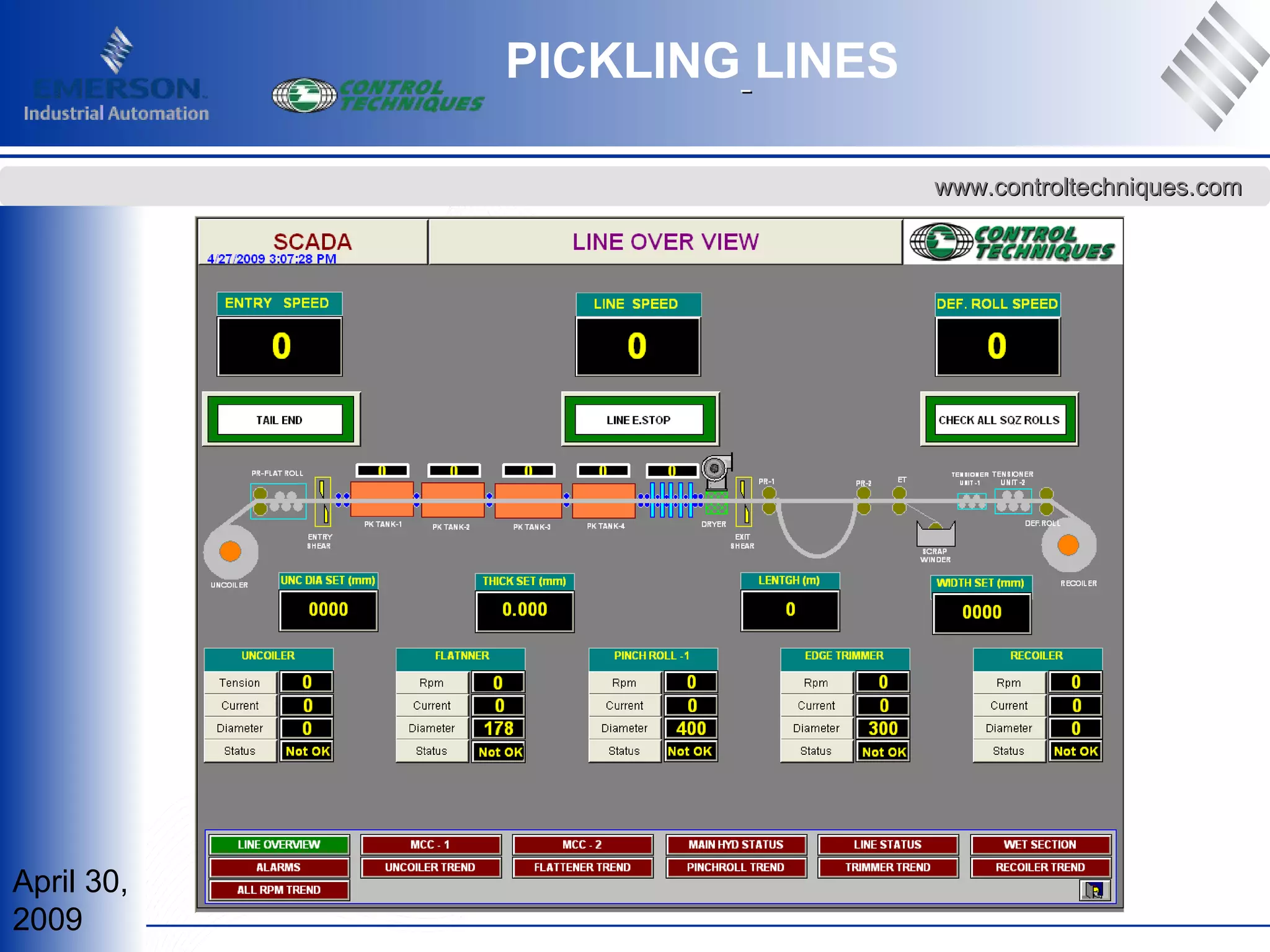

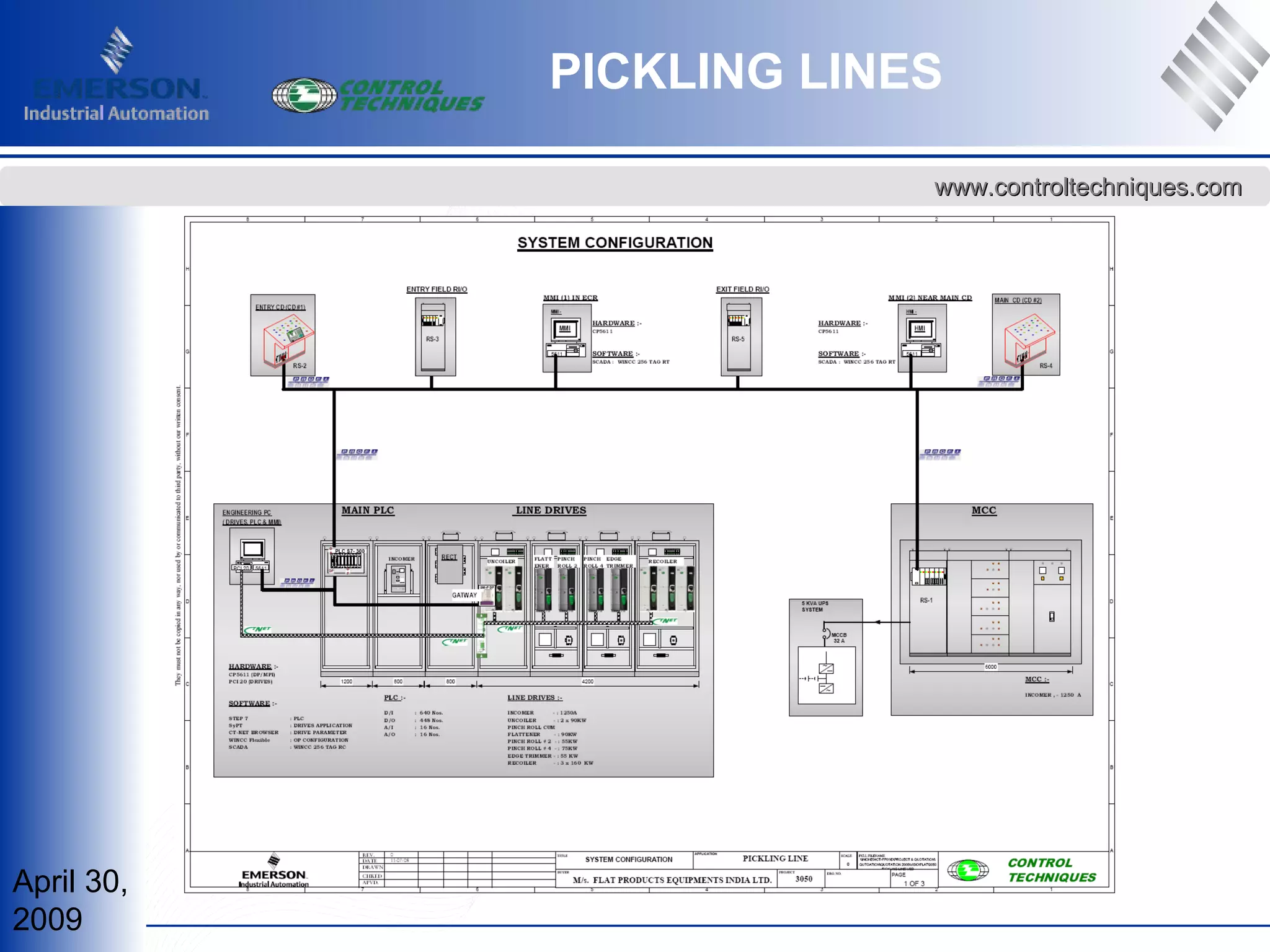

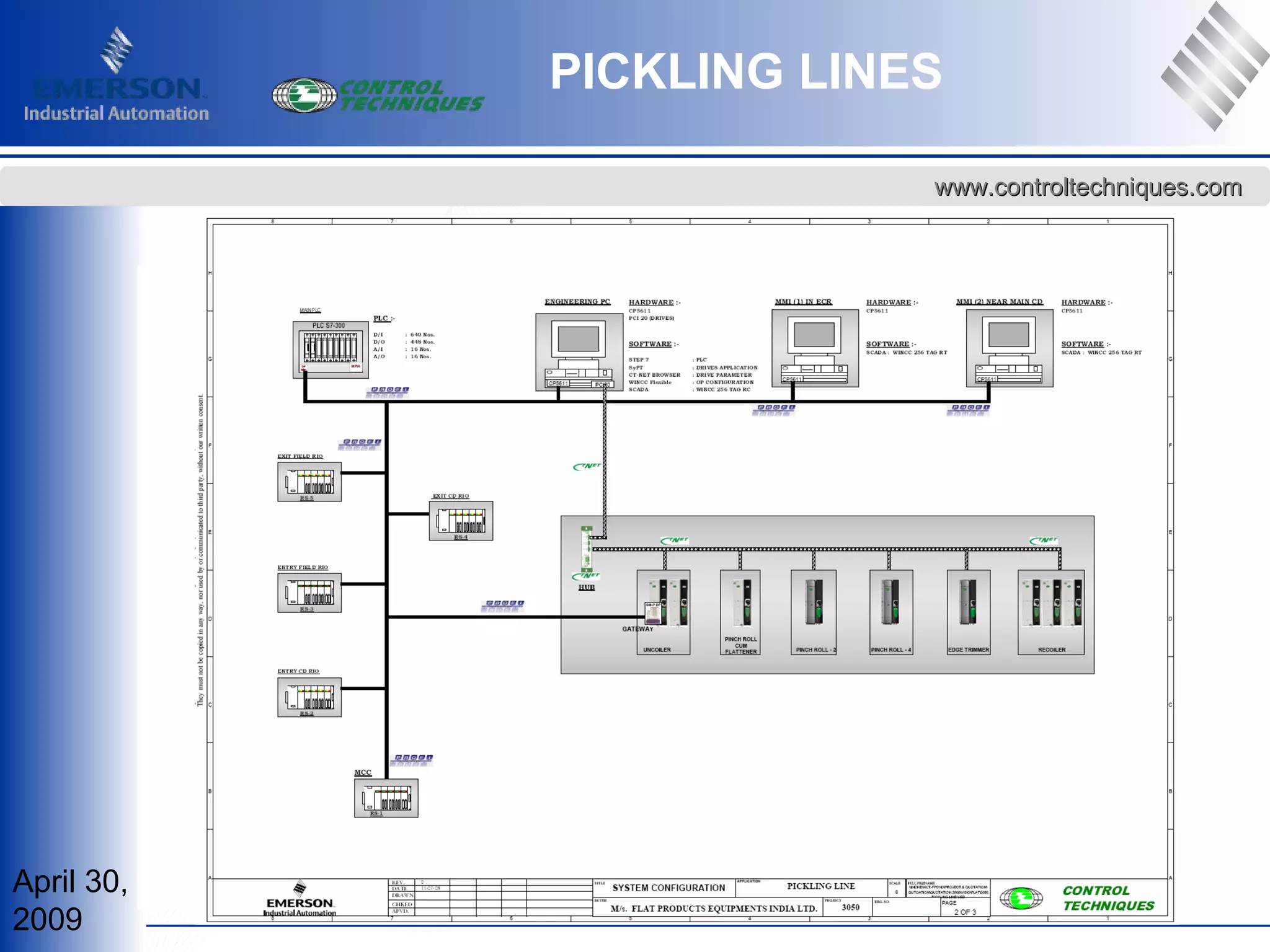

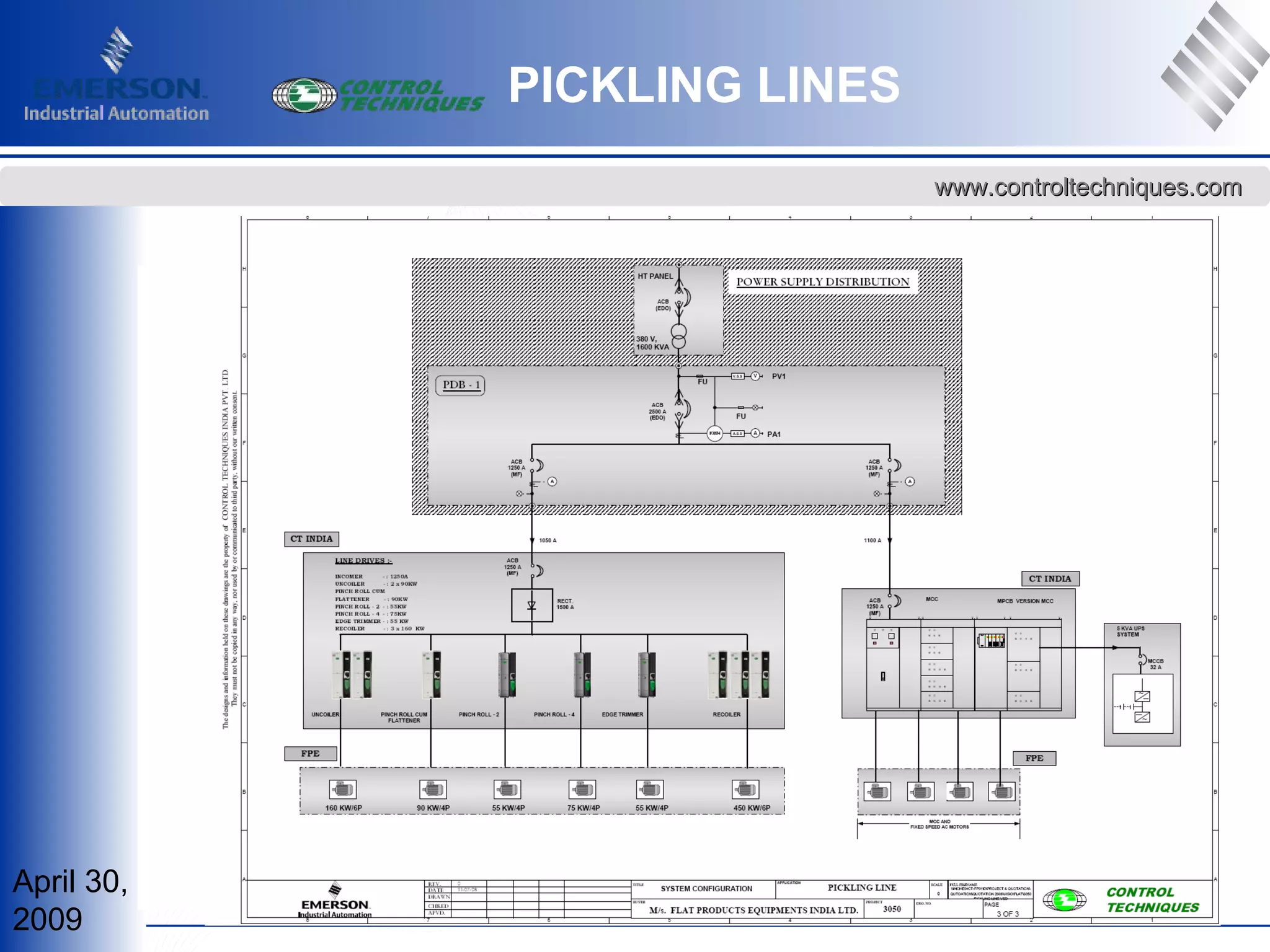

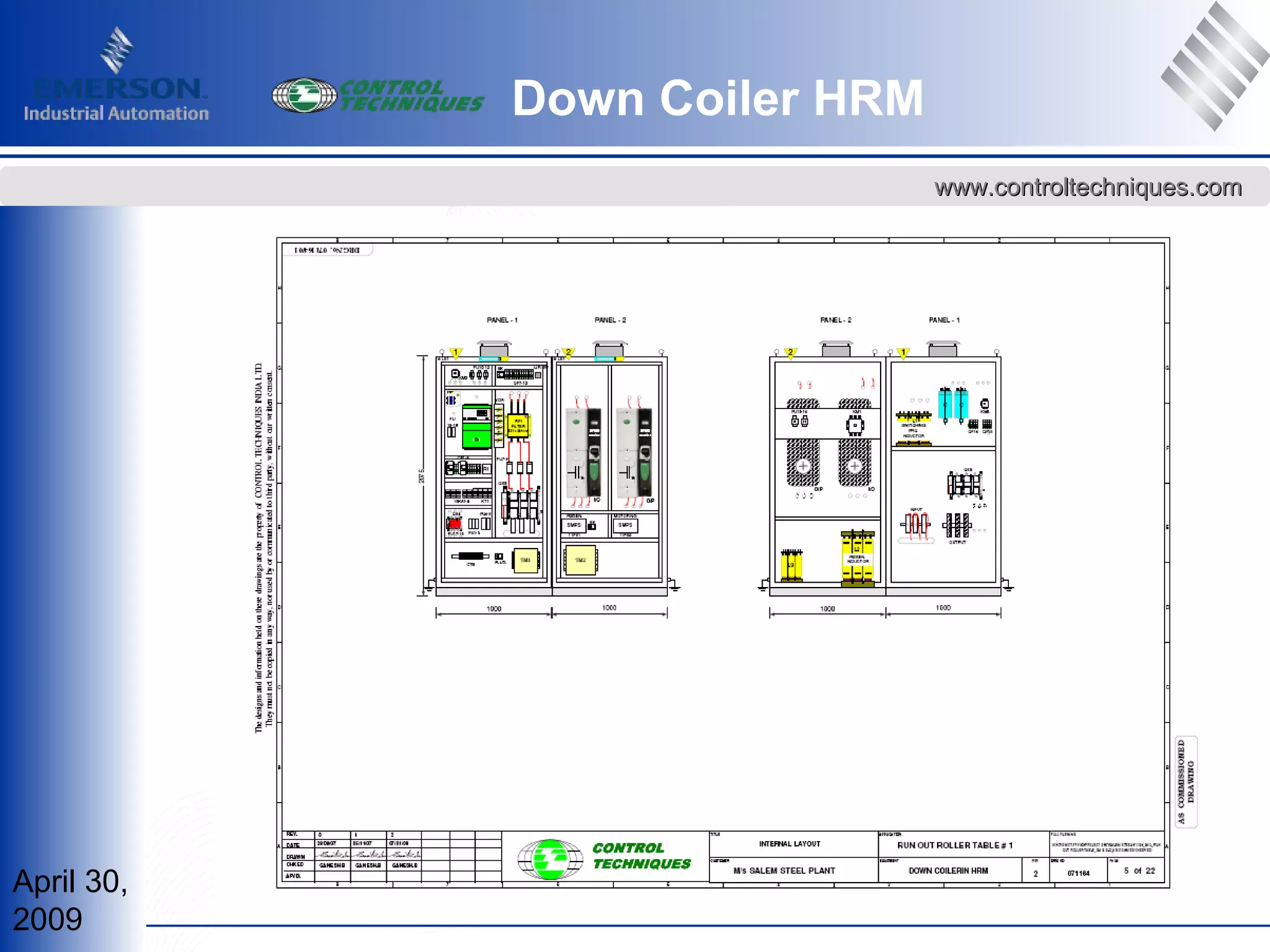

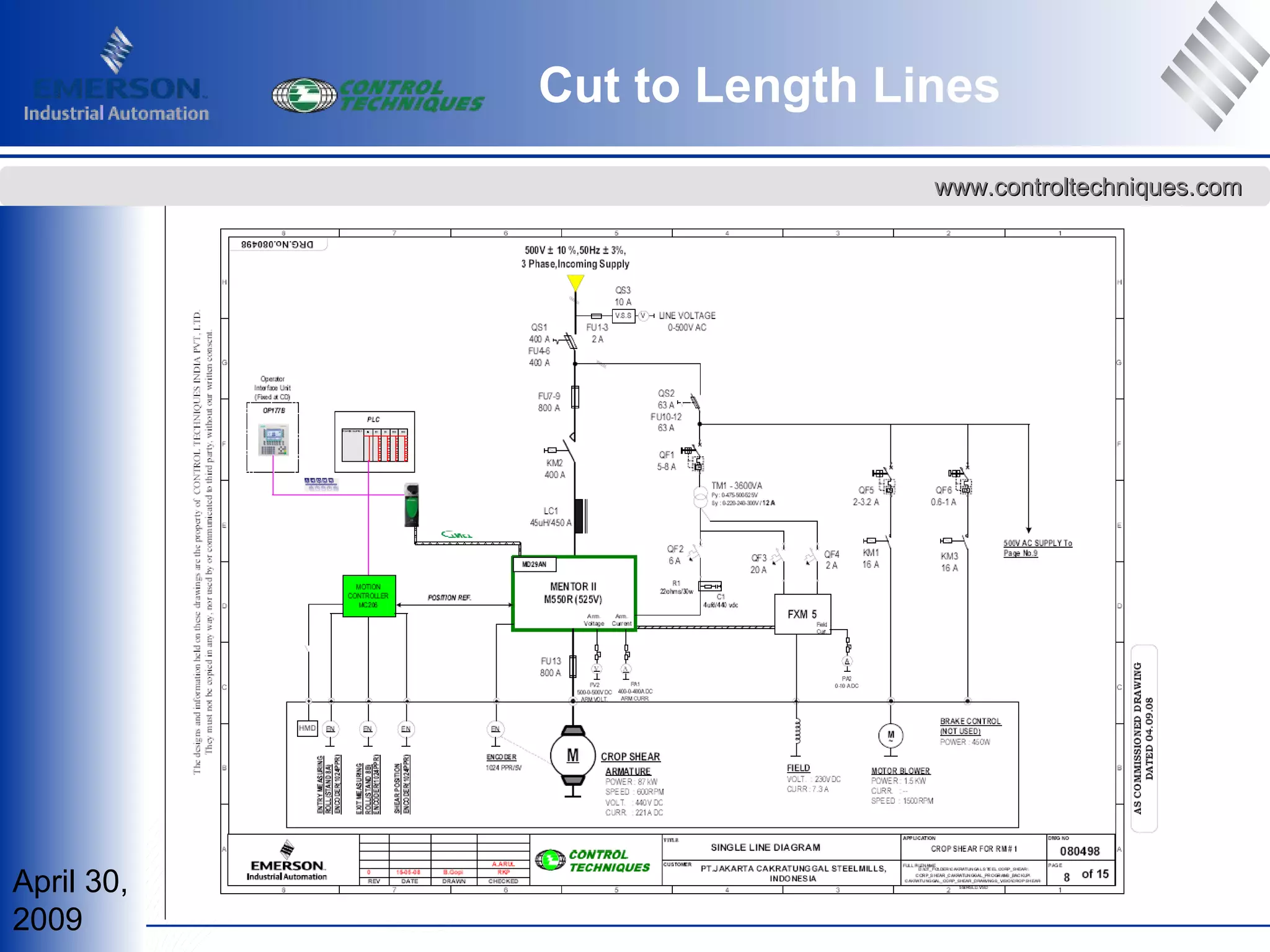

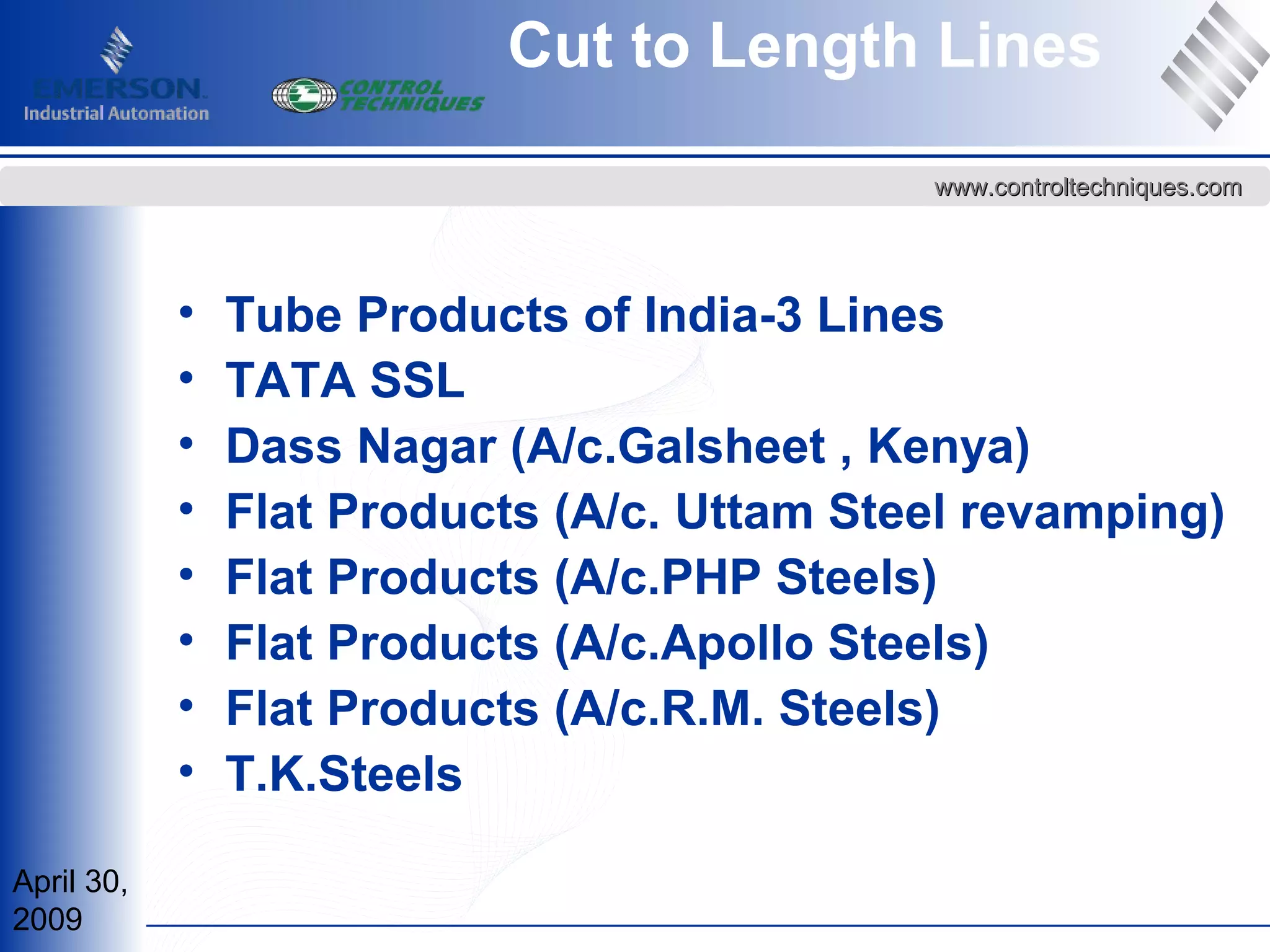

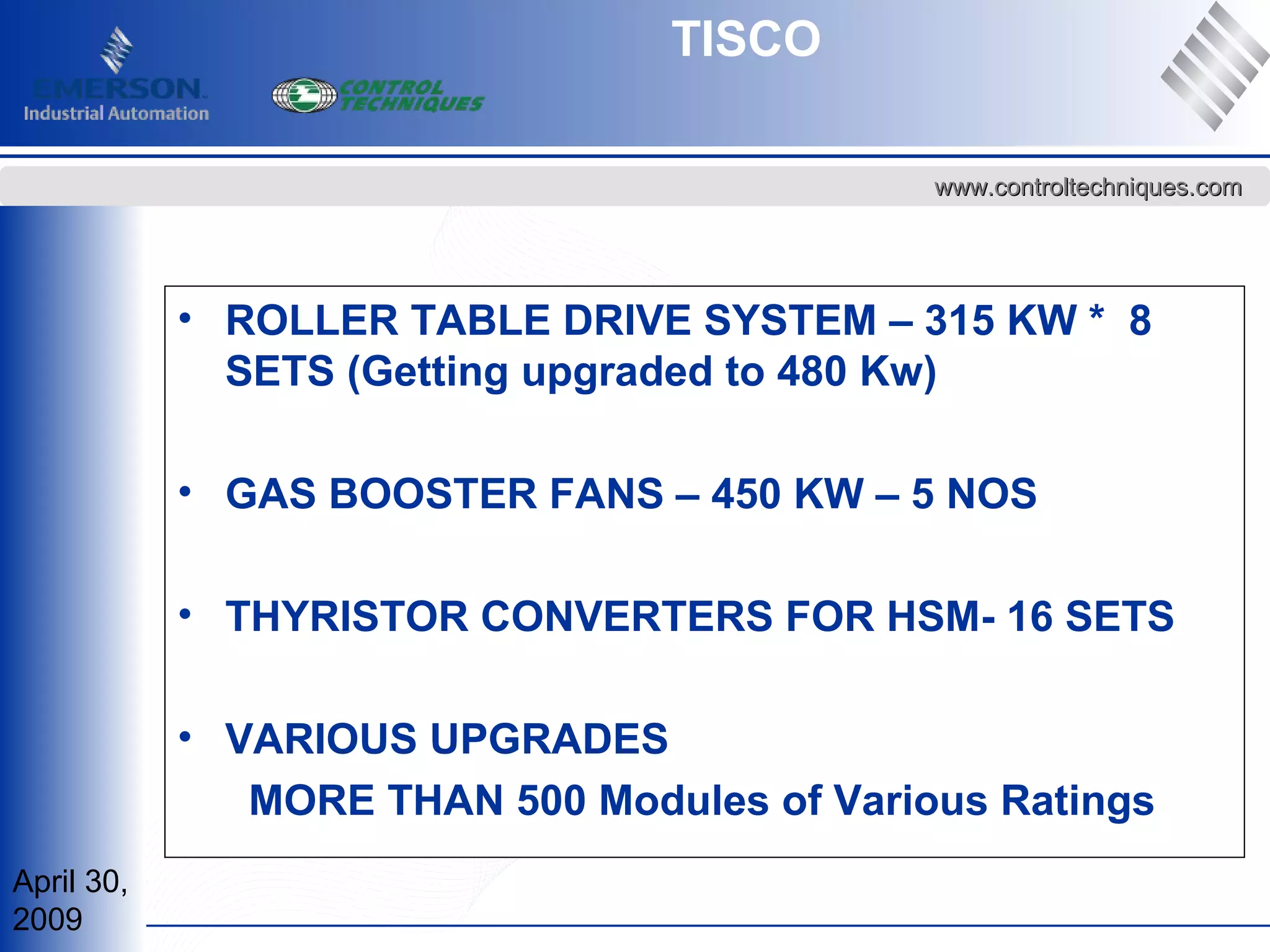

The document discusses Control Techniques' expertise in automation projects for various processes in the steel industry. It describes their work on applications like rolling mills, galvanizing lines, pickling lines, and slitting lines. It provides examples of specific projects they have completed for various steel producers around the world and details of the equipment supplied, including drives, PLCs, SCADAs, motors and more.