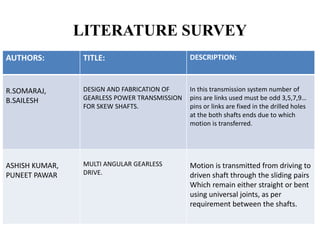

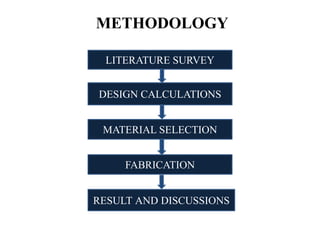

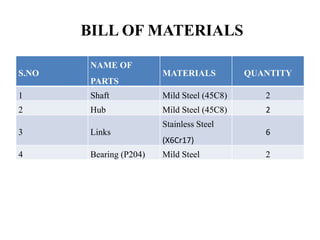

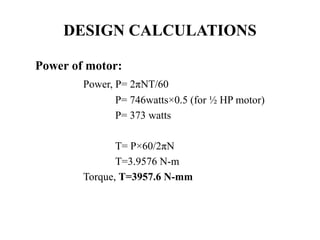

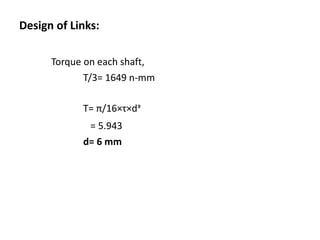

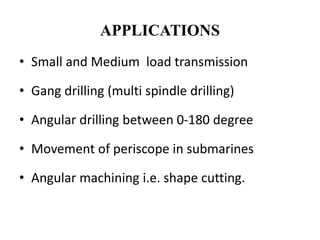

The document presents the design and fabrication of a gearless angular power transmission system by a group of mechanical engineering students under the guidance of a professor. It details the working mechanism involving multiple pins for smooth operation, design calculations for components, materials used, and various applications such as small load transmission and angular drilling. Additionally, the advantages of this system include efficiency, cost-effectiveness, and tolerance for shaft misalignment.

![Design of Shaft:

Considering 25% of overload,

Tmax= T×1.25

Tmax= 4947 N-mm

T= (π/16)×τ×dᵌ [Shear stress, τ=40N/mm²

d= 8.57 P.S.G. Design data book]

d= 9 mm

Taking Factor of Safety= 2

d= d×2

d= 18 mm](https://image.slidesharecdn.com/batch15-170725090023/85/Gearless-angular-power-transmission-system-10-320.jpg)

![Design of Hub:

Diameter of Hub,

D= 2d+13 [P.S.G. Design data book]

= 49

D= 50 mm

Force acting on the Hub,

T= F×r

F= T/r

F= 197.88 N](https://image.slidesharecdn.com/batch15-170725090023/85/Gearless-angular-power-transmission-system-11-320.jpg)

![REFERENCE

• Navneet Bardiya1, karthik.T2, L Bhaskara Rao3, School of Mechanical and

Building Sciences VIT University Chennai campus, Chennai, India Email:

navneet.bardiya2013@vit.ac.in1, karthik.t2013@vit.ac.in2,

bhaskararao@vit.ac.in3.

• Mahantesh Tanodi, Gearless Power Transmission- L Pin Coupling ,International

Journal of Ethics in Engineering & Management Education Website:

www.ijeee.in (ISSN: 2348-4748, Volume 1, Issue 5, May2014) .

• Atish Lahu Patil1,Vinay Prabhakar Jadhav2, Sagar Padmakar Patil3, Roshan

Suresh Shelar4, Gearless Mechanism in Right Angle, International Journal on

Recent and Innovation Trends in Computing and Communication. ISSN: 2321-

8169 Volume: 4 Issue: 4 [145 – 149]](https://image.slidesharecdn.com/batch15-170725090023/85/Gearless-angular-power-transmission-system-16-320.jpg)